Design and Engineering

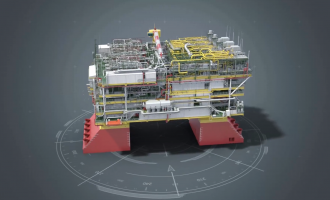

CNGS Engineering performs a full range of engineering works both within turnkey contracts (EPIC) and as specific activities, depending on the Customers’ needs.

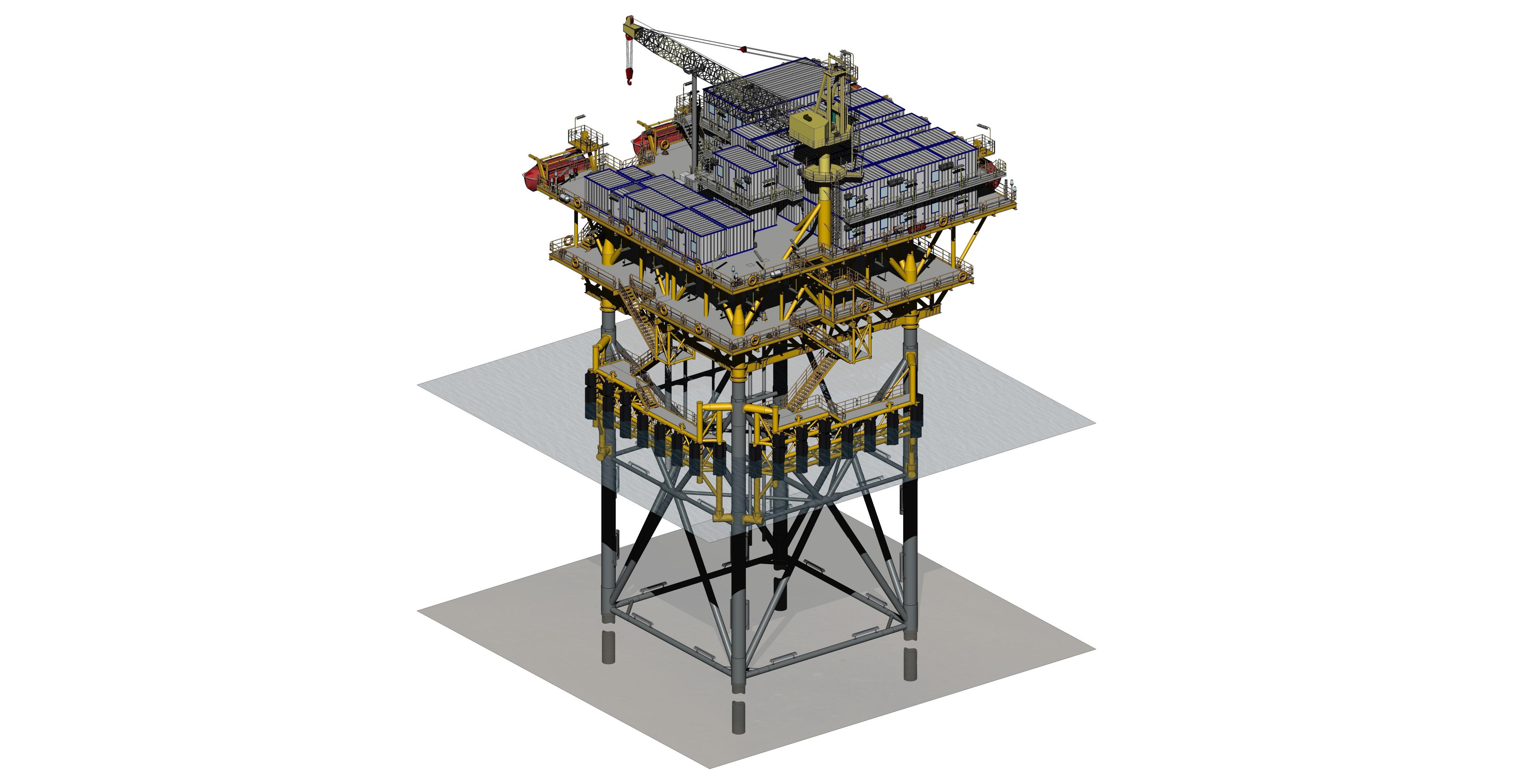

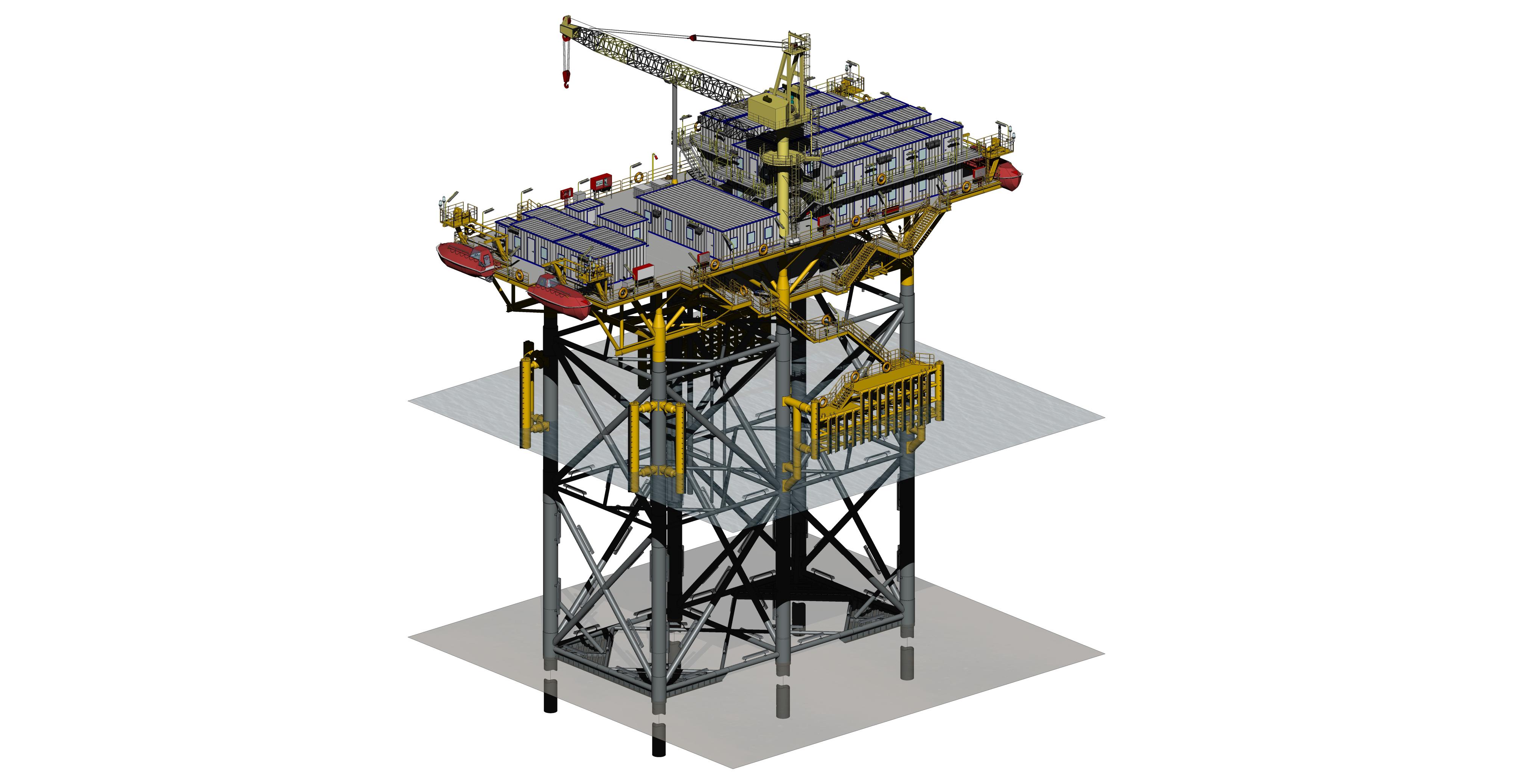

The company's design division provides for the development of design documentation for the construction of new, as well as for reconstruction, overhaul and upgrade (modernization) of existing oil and gas facilities, both onshore and offshore, including but not limited to the following:

- Concept studies

- Feasibility study

- Cost and weight estimation

- Process identification

- HSE

- Concept formulation

- FEED

- Weight and cost estimation

- Identification of equipment sizes and auxiliary systems engineering

- Safety and control system philosophies

- MTOs and specifications for long-lead equipment items

- Installation procedures

- Development of EPC bidding documentation

- Verification of design solutions

- Detail Engineering

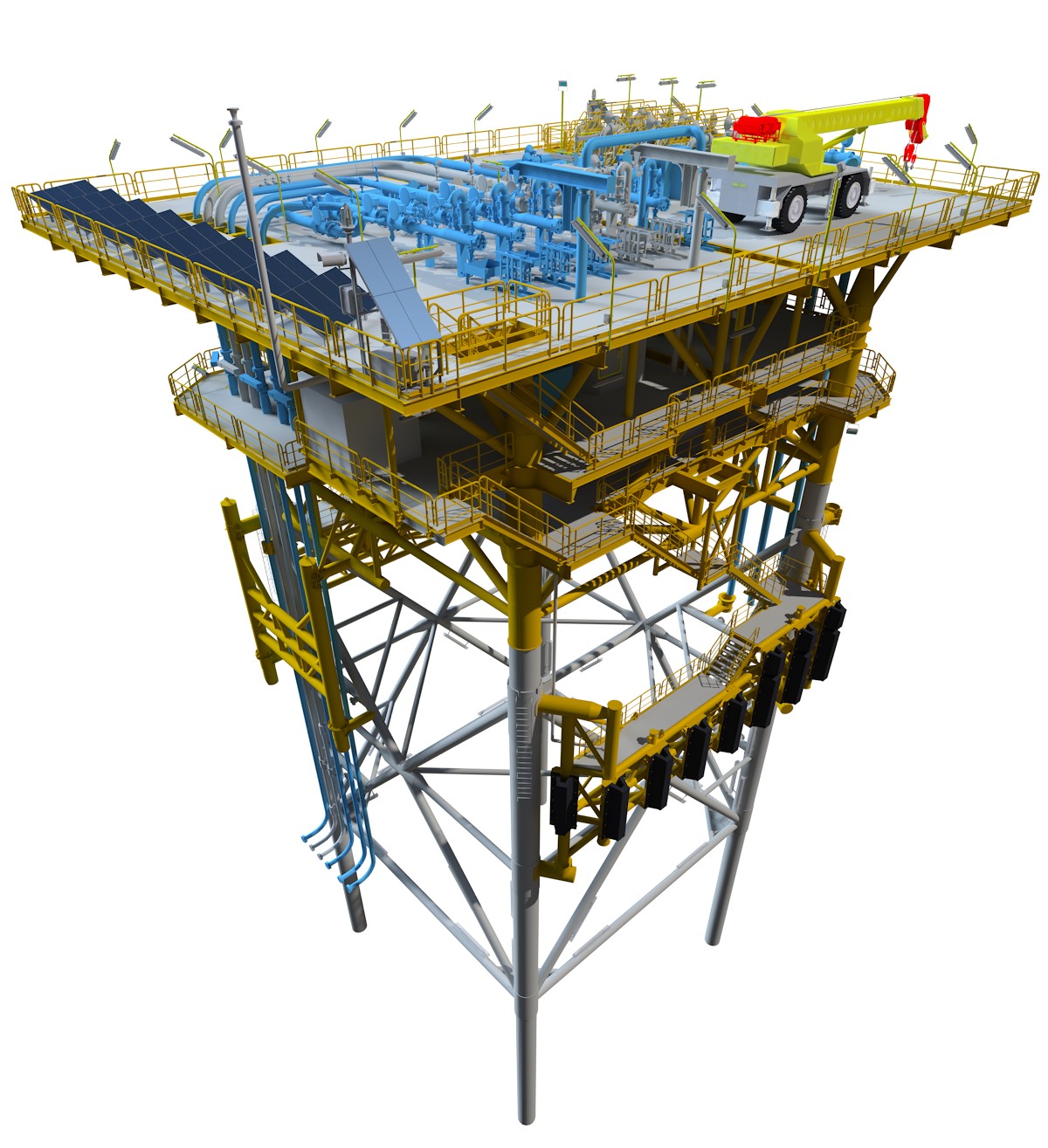

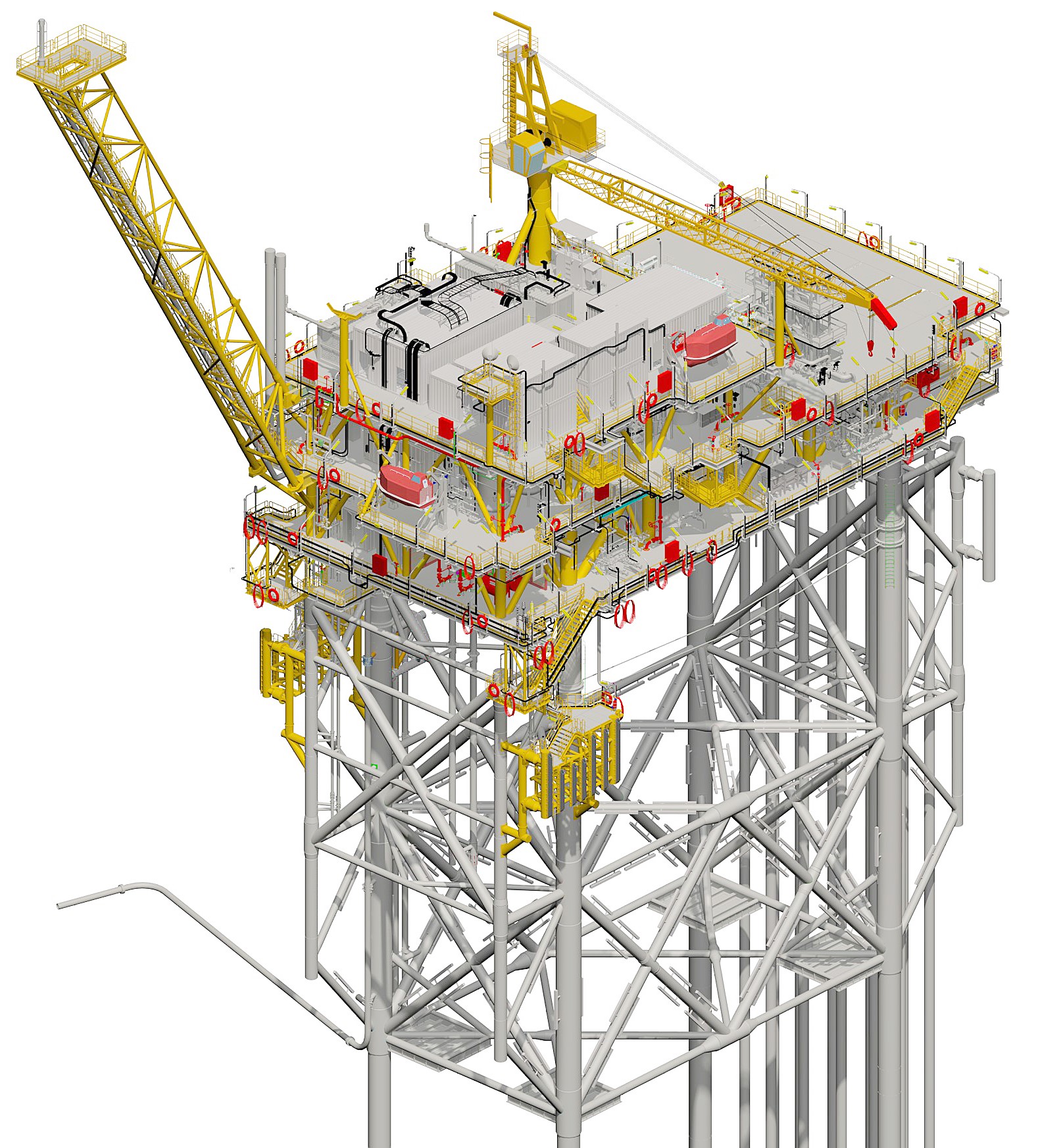

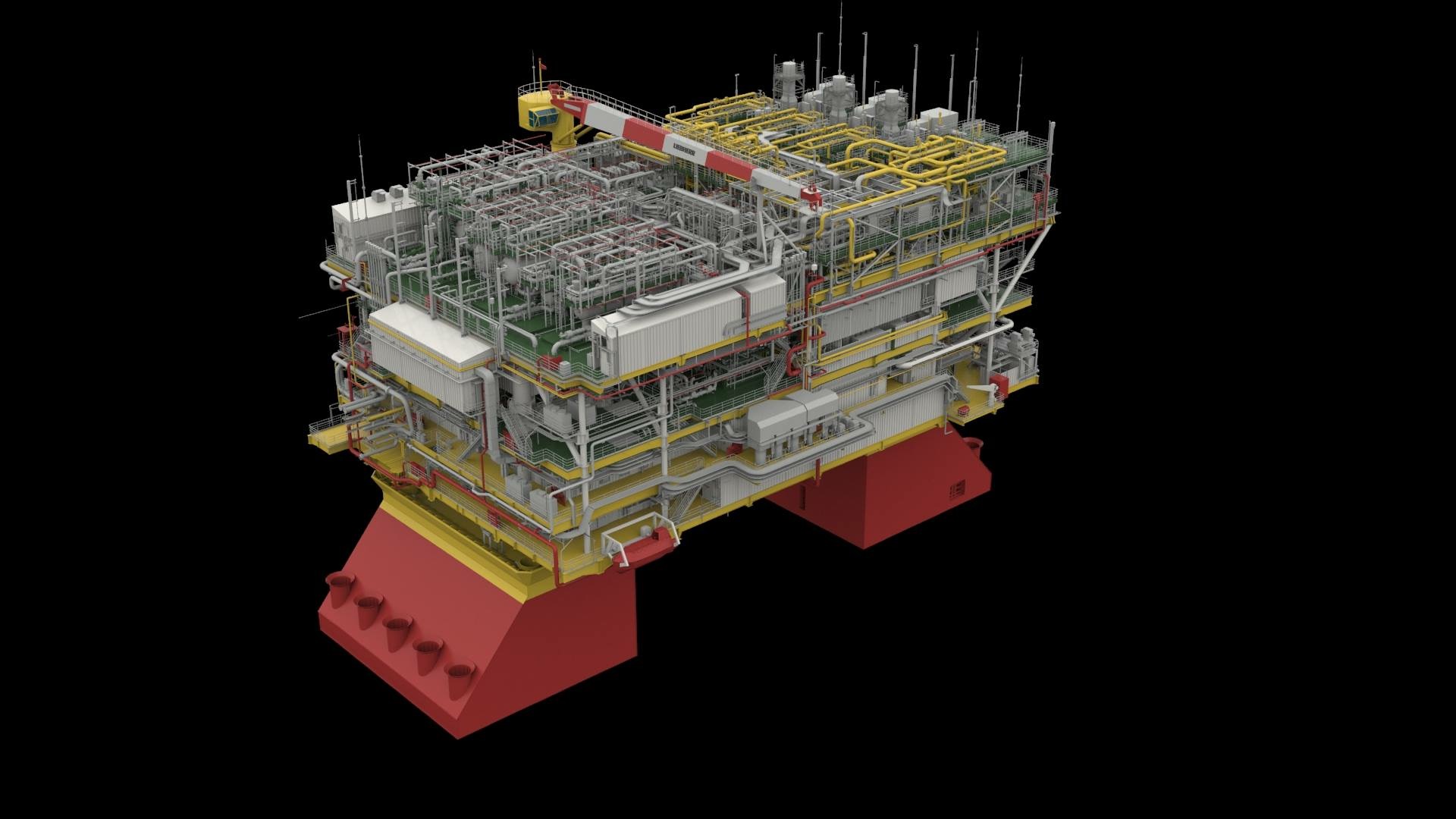

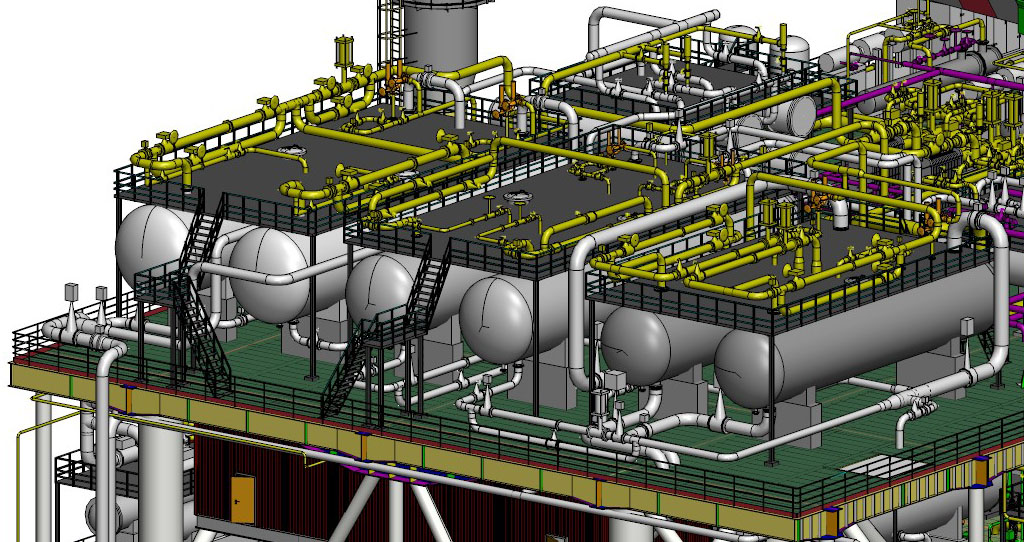

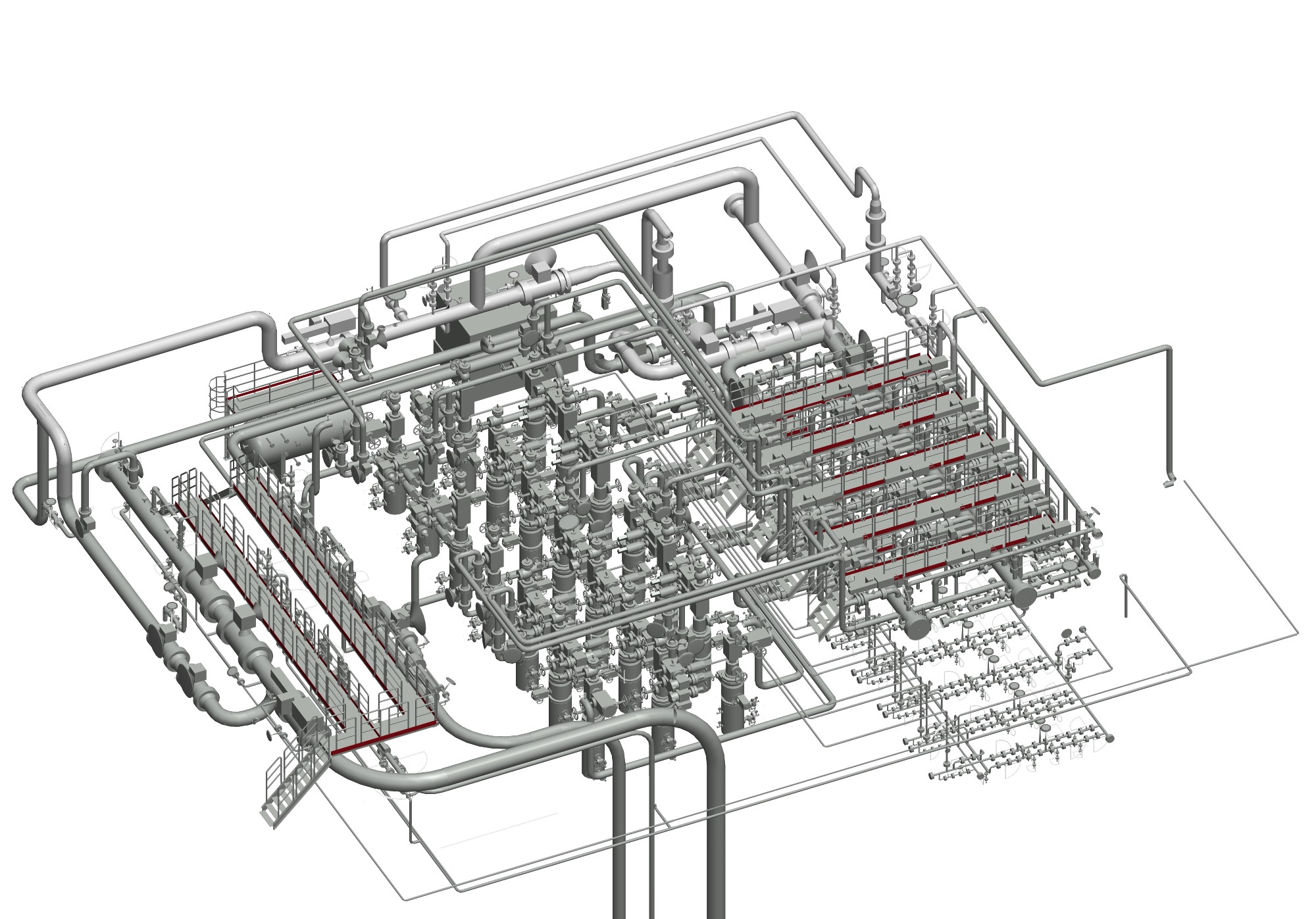

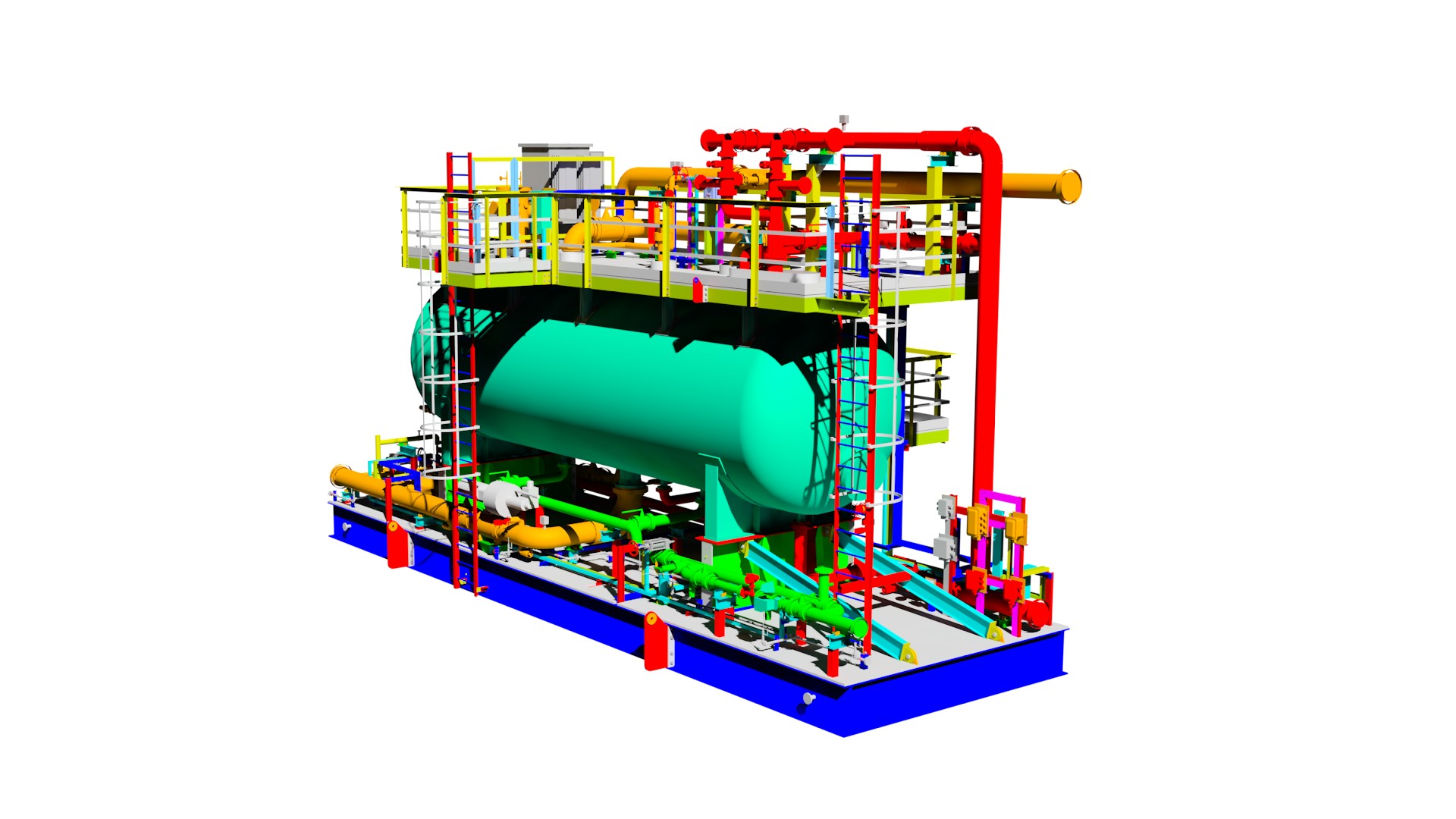

- Design of equipment and piping layouts using CAD-systems

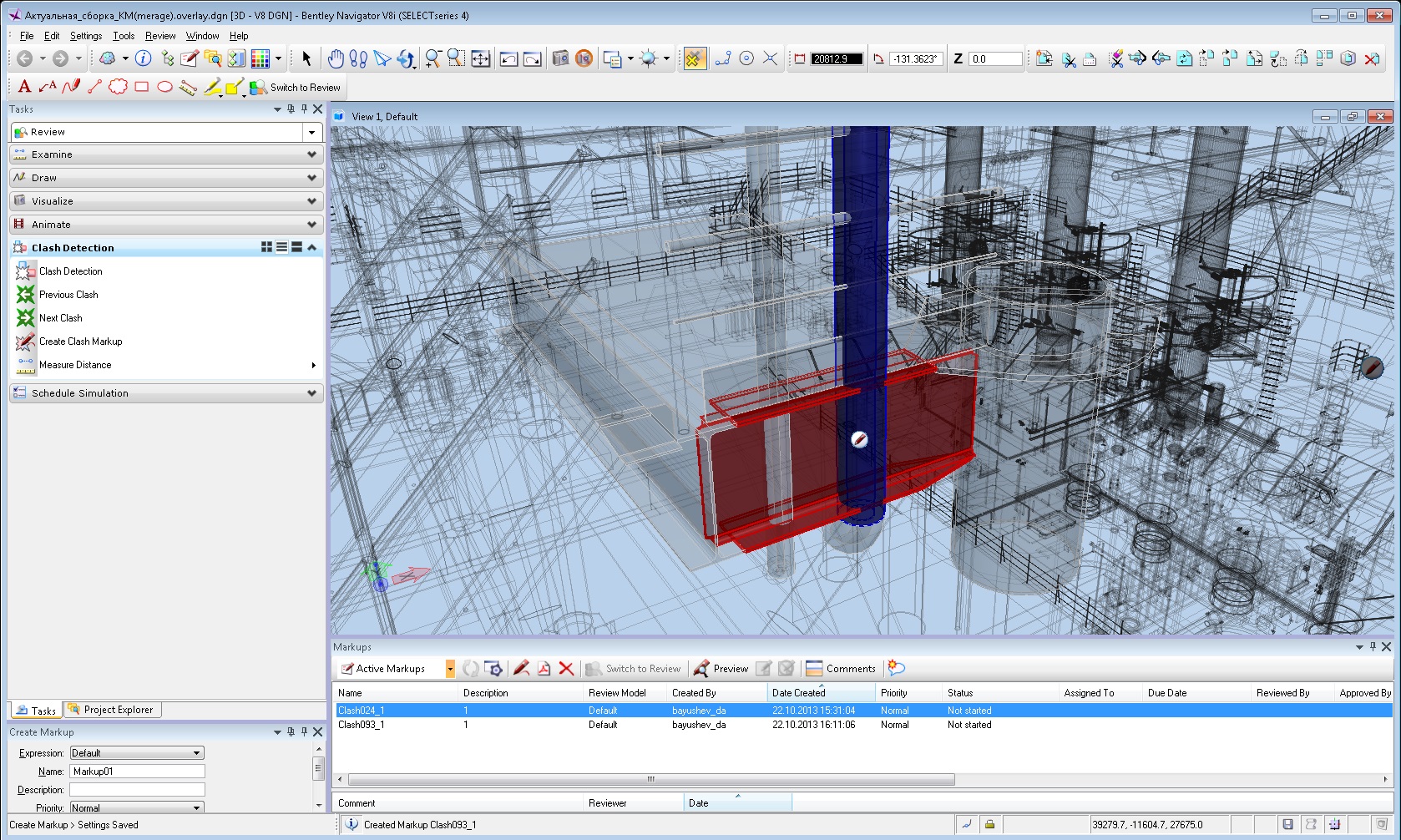

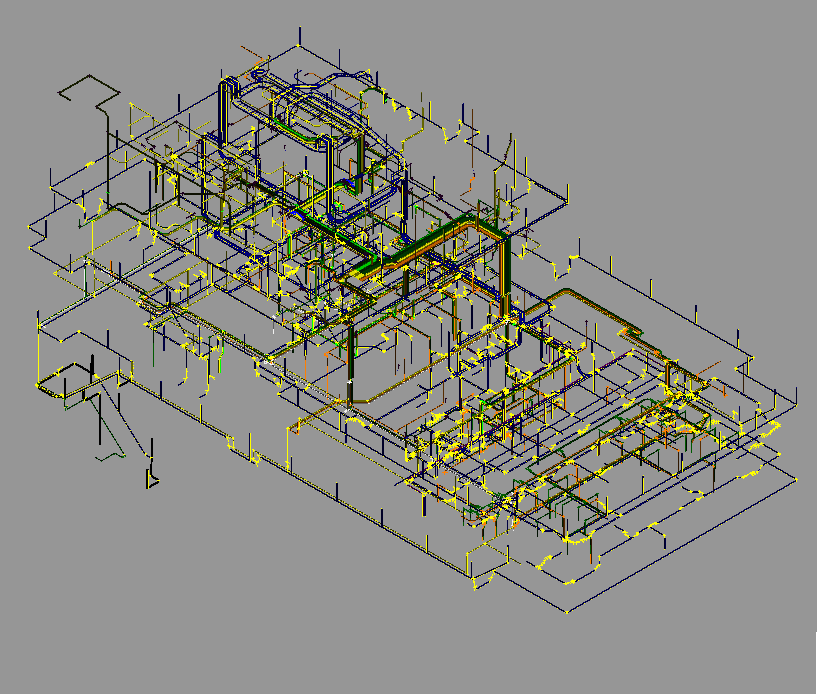

- 3D-modelling with collision control

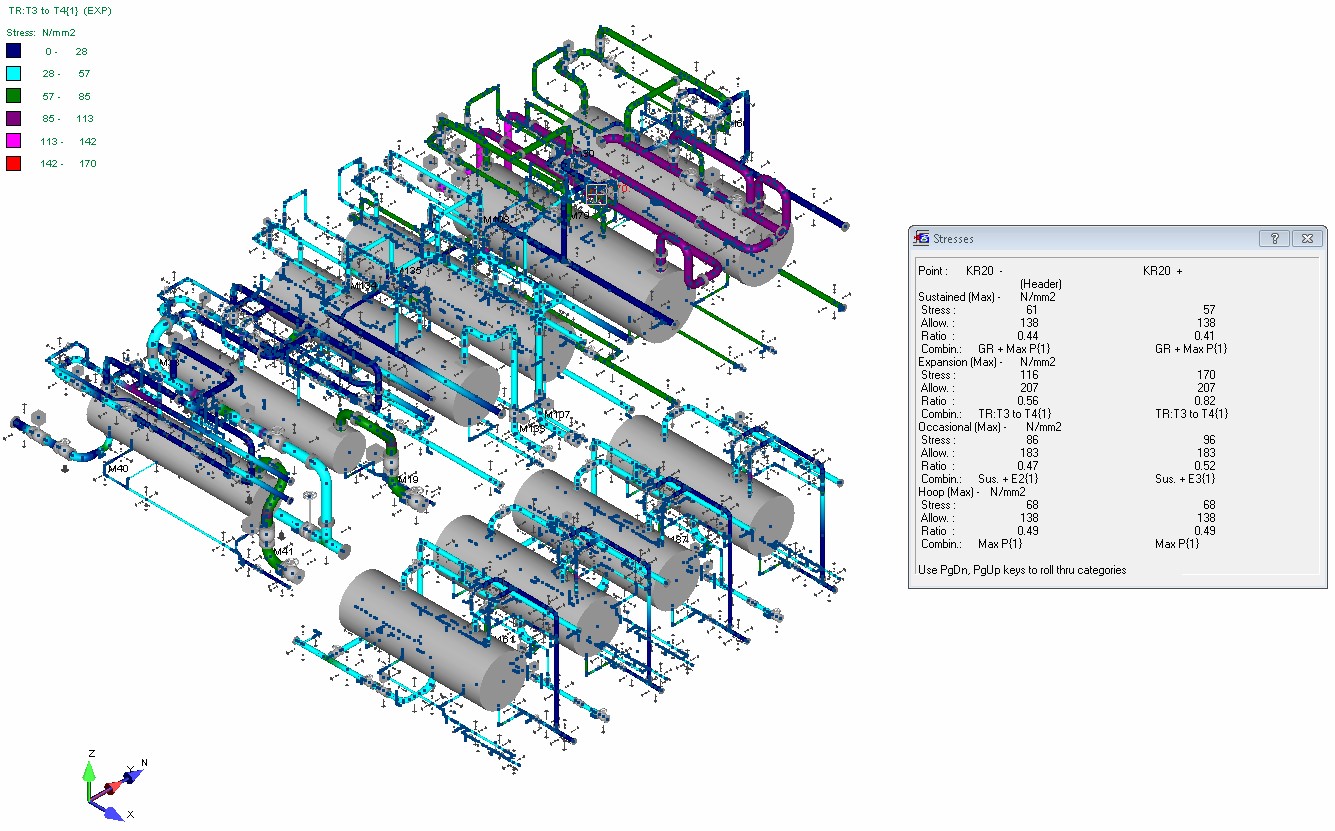

- Piping flexibility and strength analysis

- Design review sessions

- Development of equipment specifications

- Processing and updating of specifications

- Material selection philosophies

- Development of technical documentation for procurement of materials and equipment

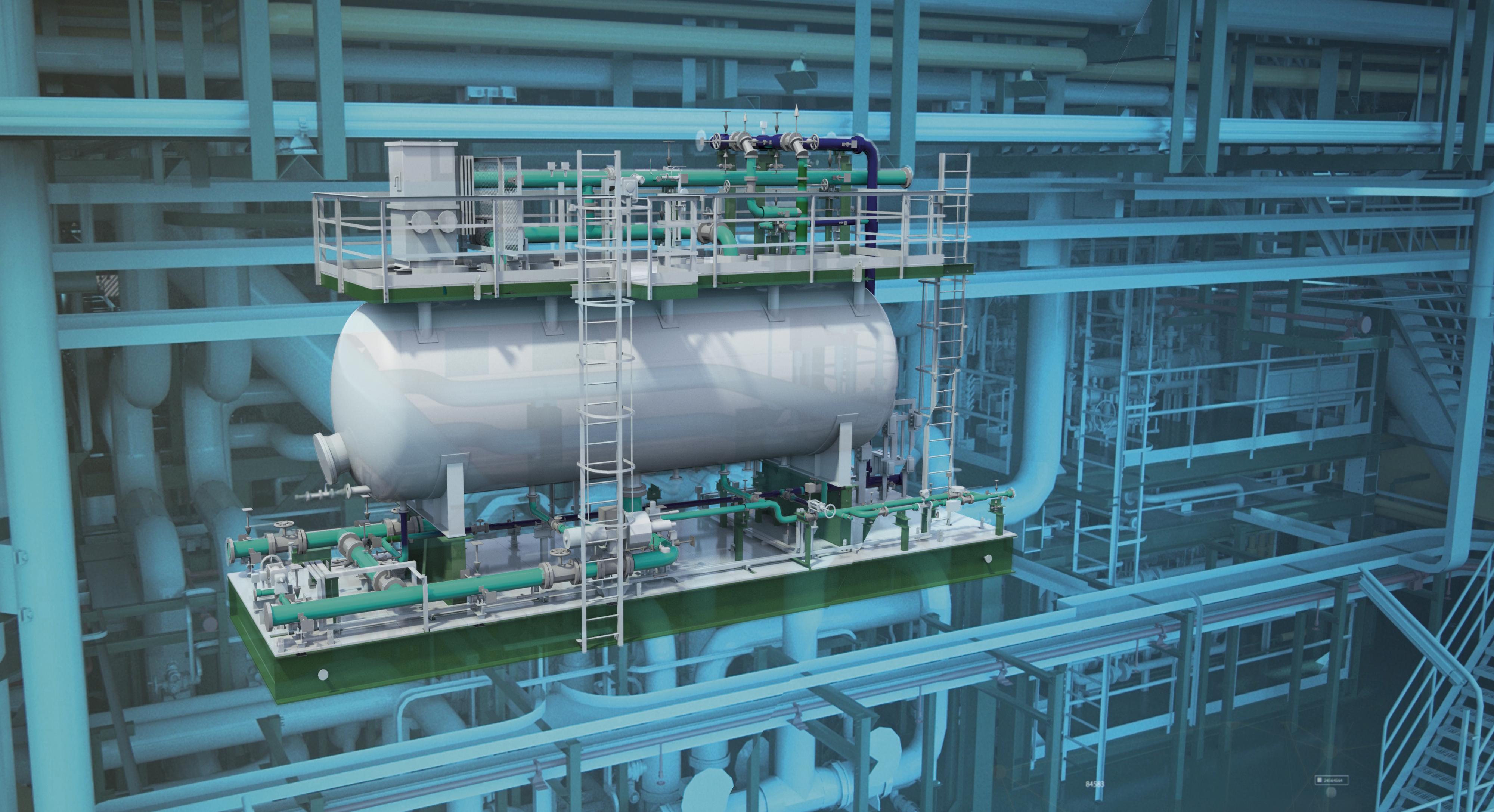

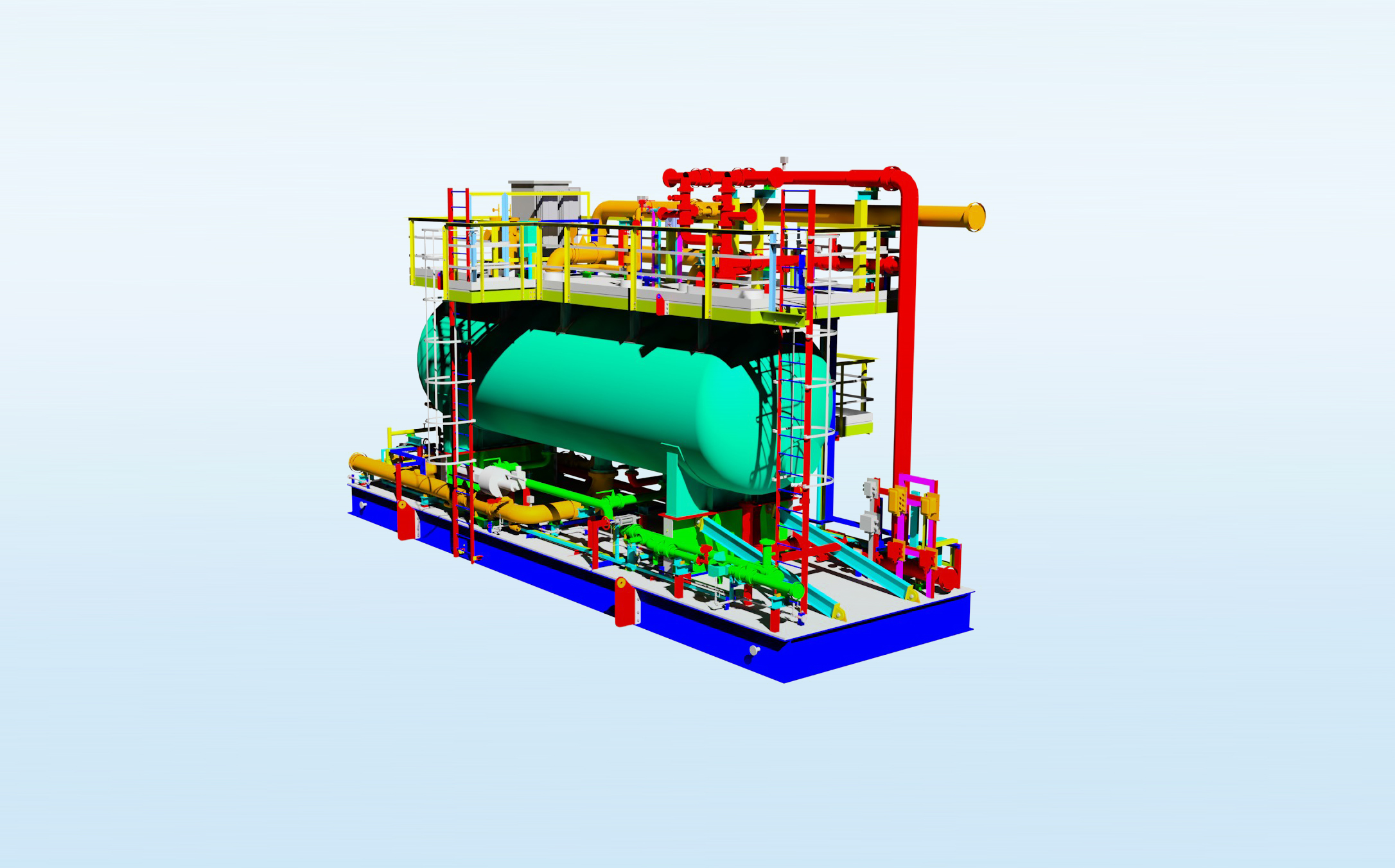

- Design of skids

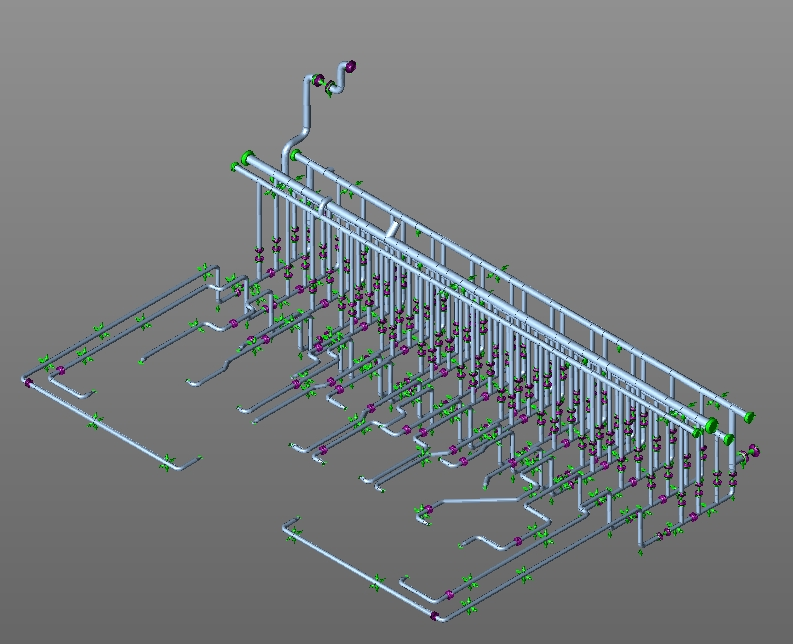

- Fire-fighting systems calculations

- Process safety, HSE

- HSE manuals, HSE risk management

- Risk consequence modelling and ALARP demonstration

- Preparation and participation in HAZID, HAZOP, SIL sessions

- Safety and process shut-down philosophies

- Hazardous areas layouts

- Design solutions assessment and verification

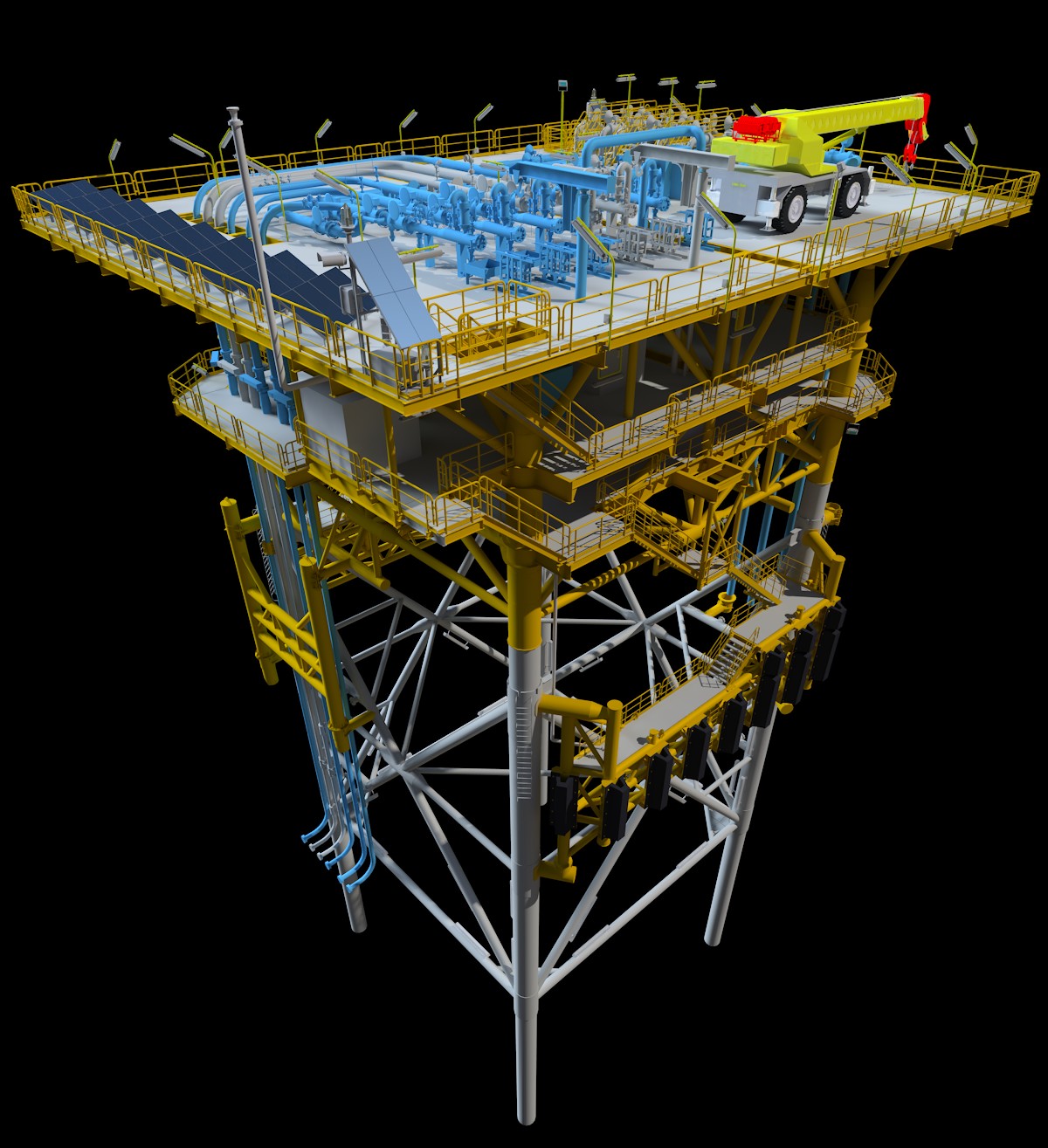

- Process design

- Production, preparation, compressing, distribution and transportation of hydrocarbons

- Process simulation and hydrodynamic calculation

- Equipment sizing and evaluation of its configuration

- Process safety, HAZID and HAZOP

- Facilities optimization and modification

- Design of zero discharge systems and systems having minimum impact on the environment

- Design solutions assessment and verification

- Electrical, instrumentation and telecommunication systems design

- Design of electrical power supply systems

- Analysis of transition processes, analysis of voltage and current harmonical components

- Electrical power supply control systems

- Calculation of safety relay set points

- Classification of hazardous areas and ignition control

- Lighting design and calculation

- Power management and analysis

- Equipment, cable routes, cable and pipe routes 3D-modelling

- Ecologically clean energy regeneration sources (solar panels, wind energy)

- Design of fail-safe security systems

- Design of SCADA/DCS

- Arrangement of flame and gas detectors

- Functional safety and SIL assessment

- Design of telecommunications

- Piping and mechanical design

- Design of equipment and piping layouts using CAD-systems

- 3D-modelling with collision control

- Piping flexibility and strength analysis

- Design review sessions

- Development of equipment specifications

- Processing and updating of specifications

- Material selection philosophies

- Development of technical documentation for procurement of materials and equipment

- Design of skids

- Fire-fighting systems calculations

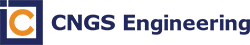

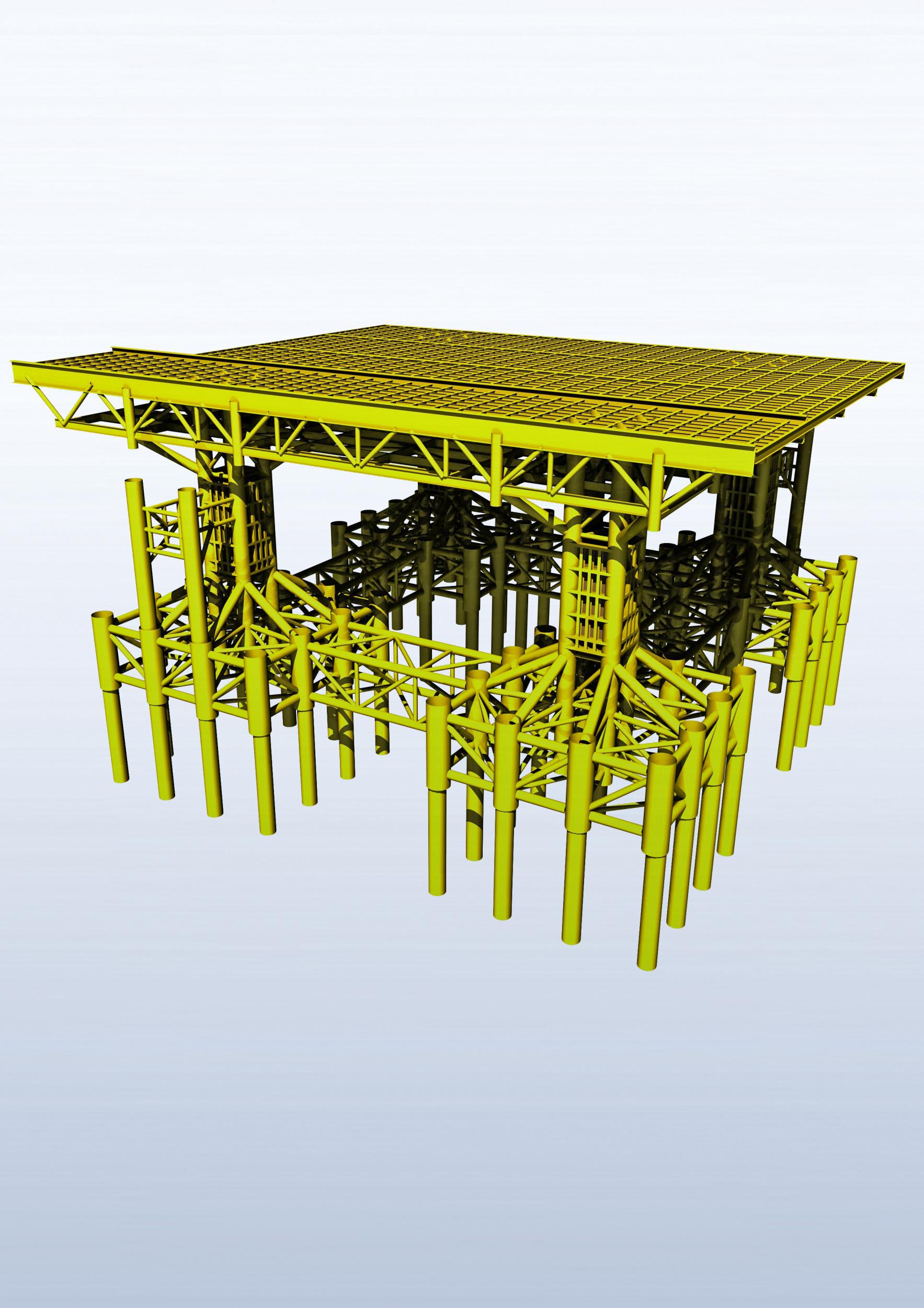

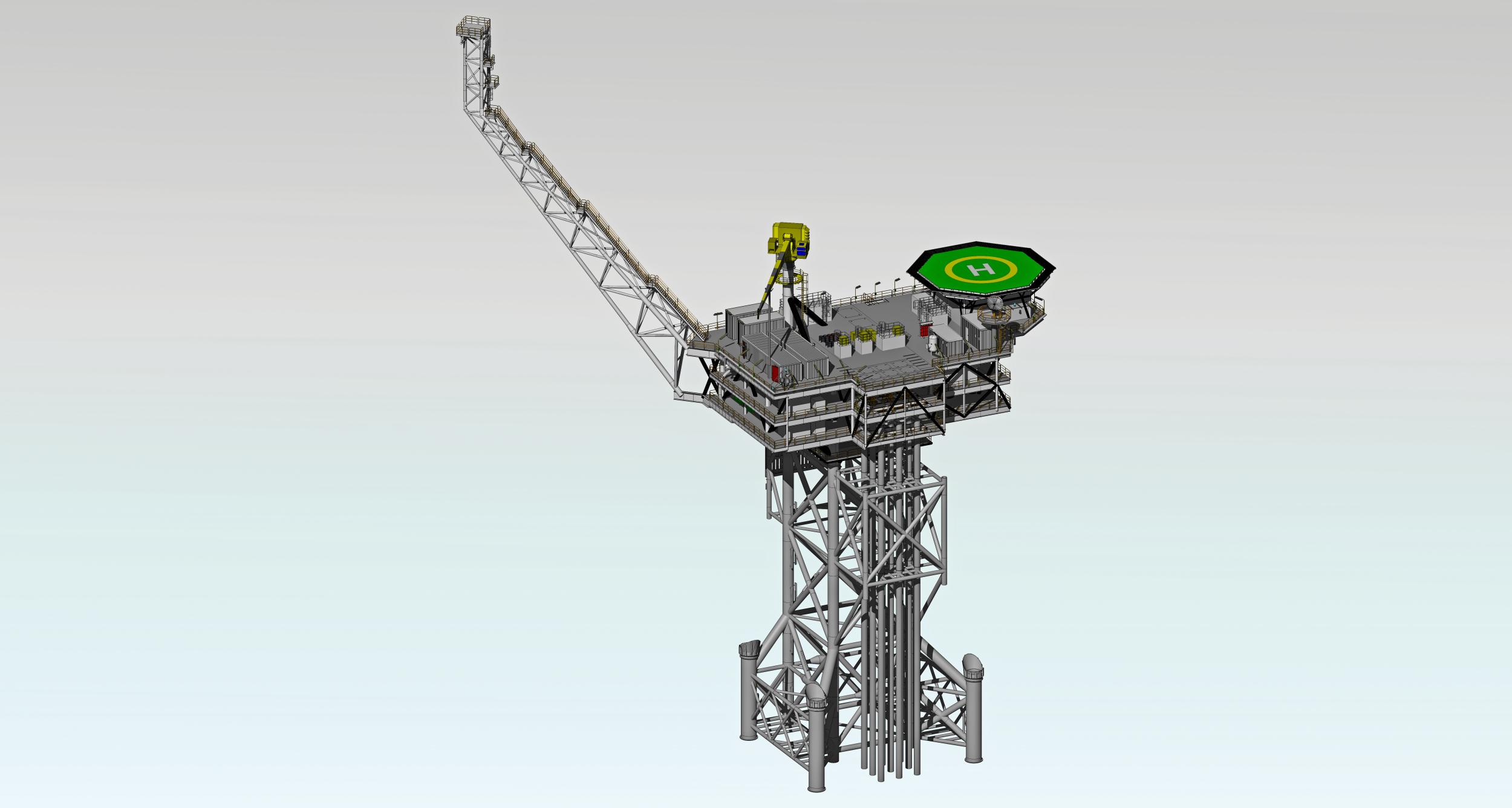

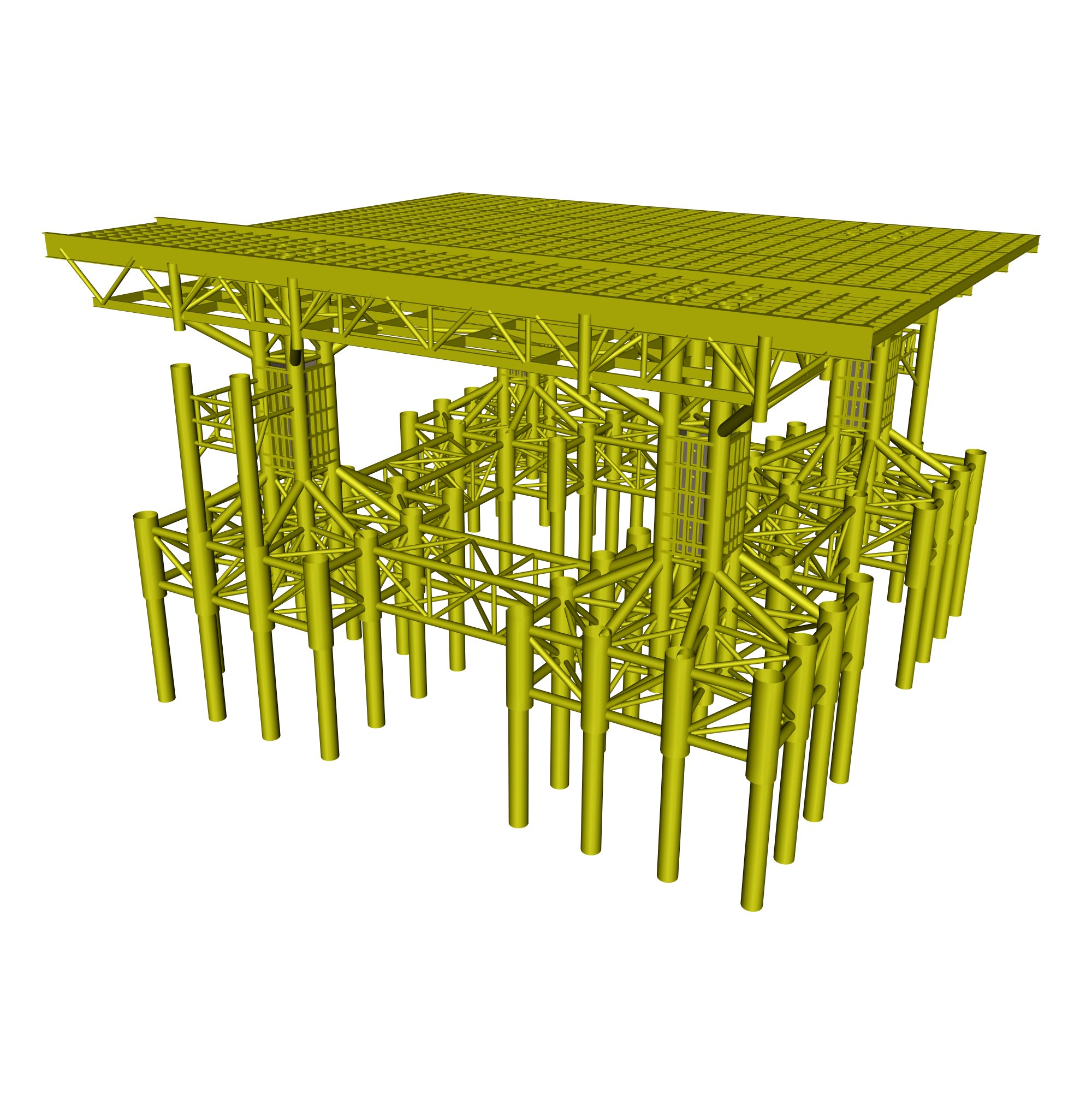

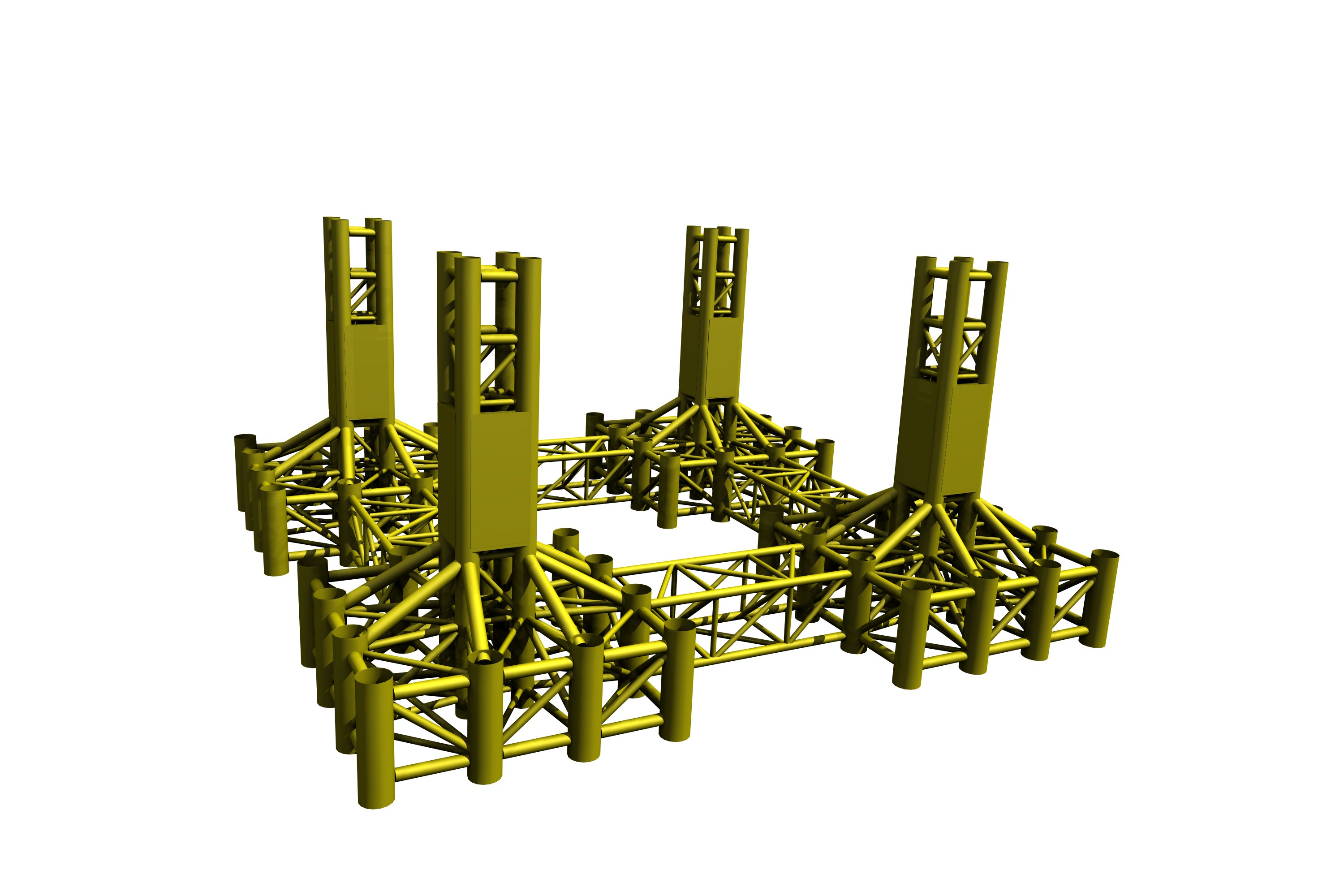

- Buildings and facilities structural design

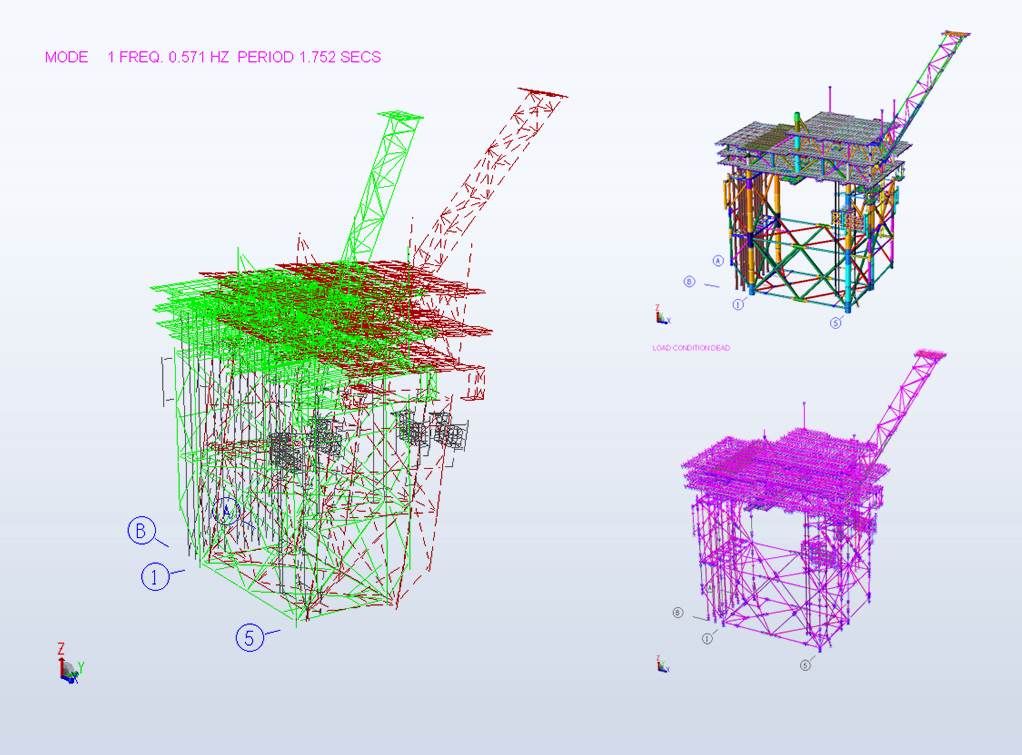

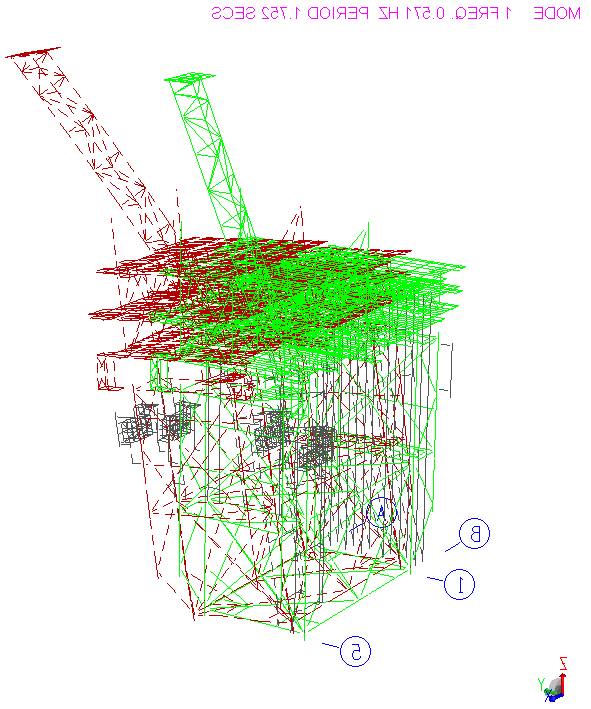

- Structural strength analysis, in-depth finite-element analysis

- Dynamic impact analysis

- 3D-modelling, providing collision control

- Assessment of vibration and noise levels

- Construction supervision and verification of design solutions

- Offshore facilities decommissioning

- Linear facilities design

- Hydrothermal calculations and modelling of various conditions of fluid transportation

- Calculations of facilities stress-strain behavior

- Pipeline stability analyses

- Linear facilities laying analyses

- Cathodic protection calculations

- Method statements and construction organization projects of subsea pipelines and cable lines

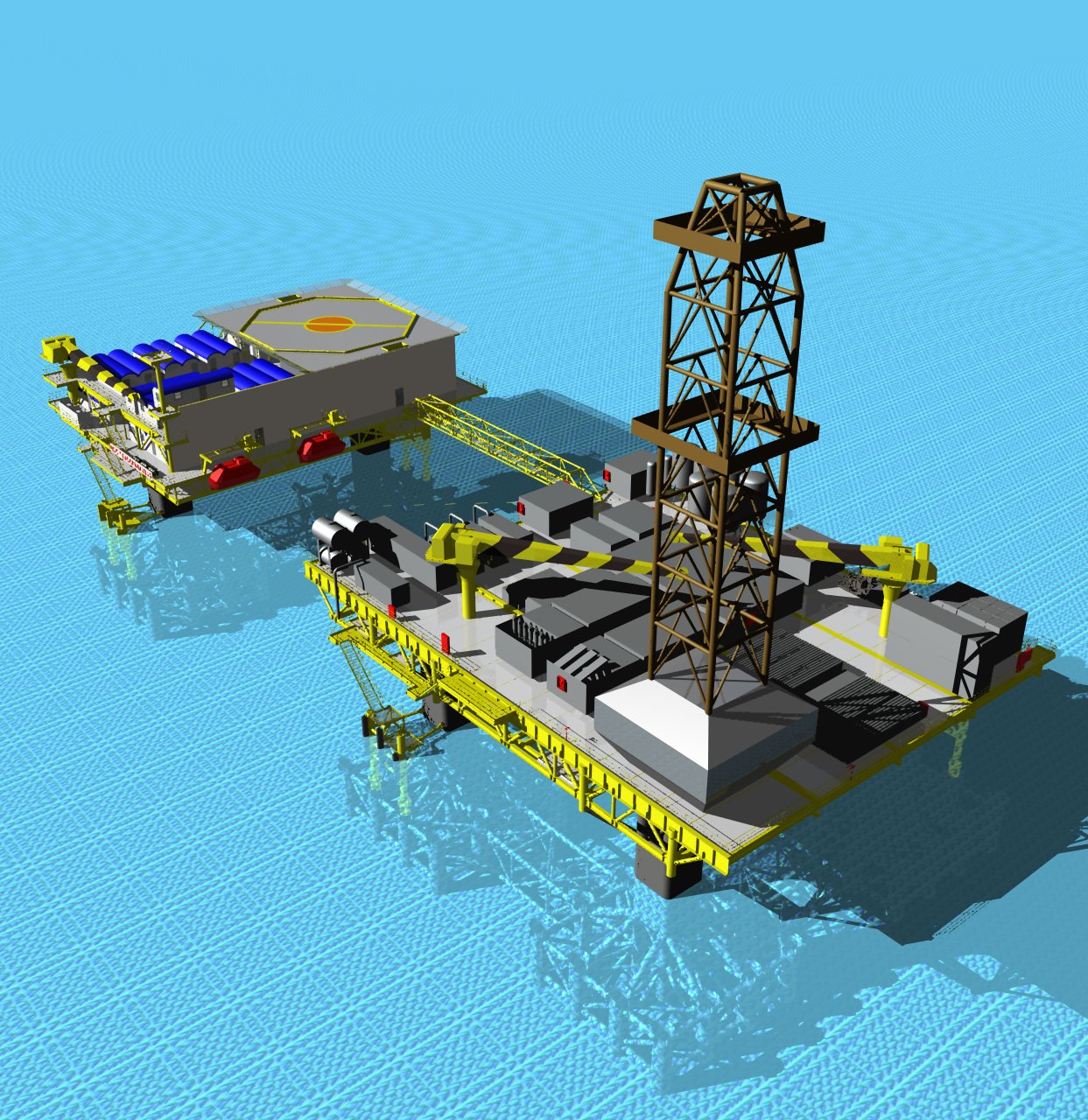

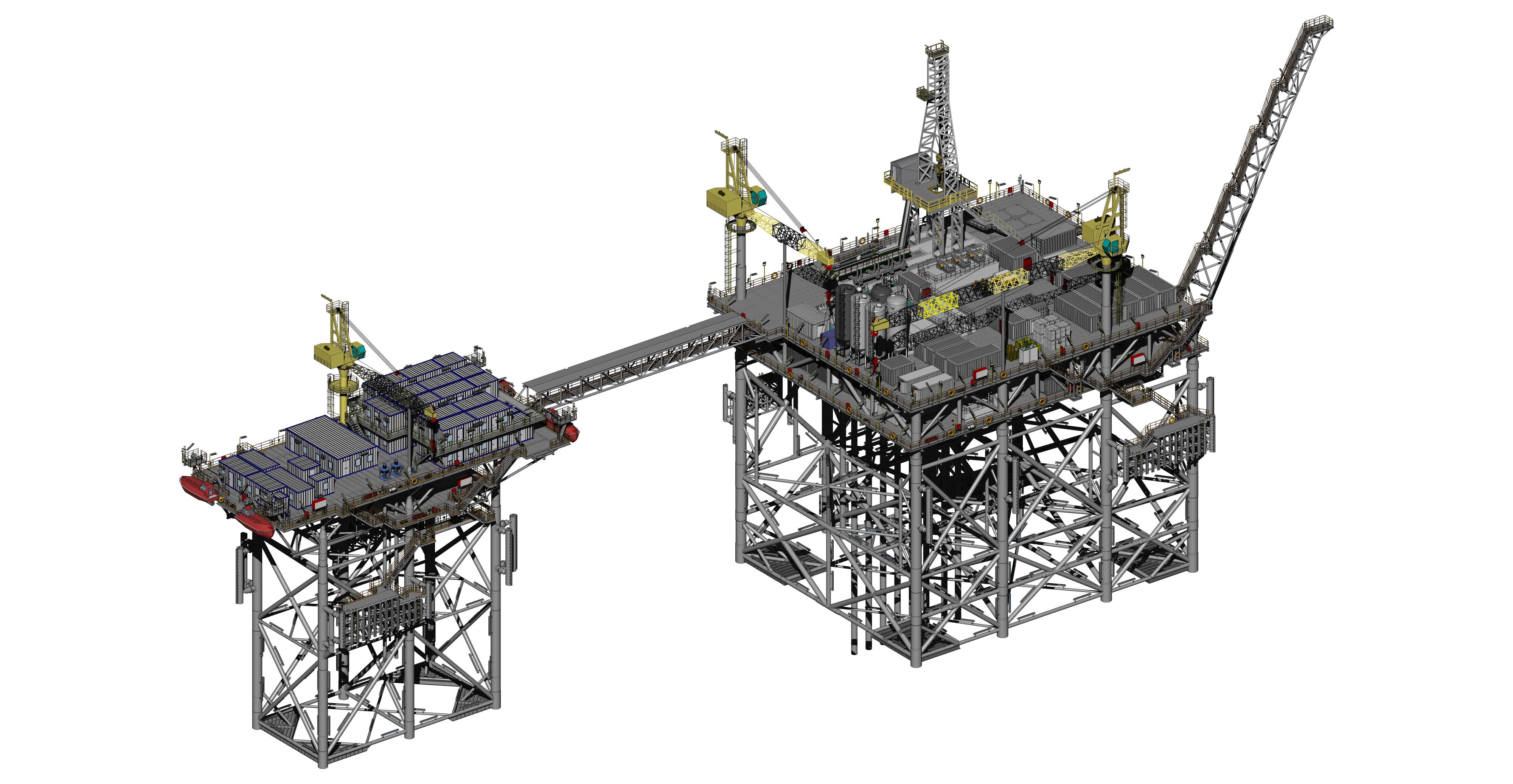

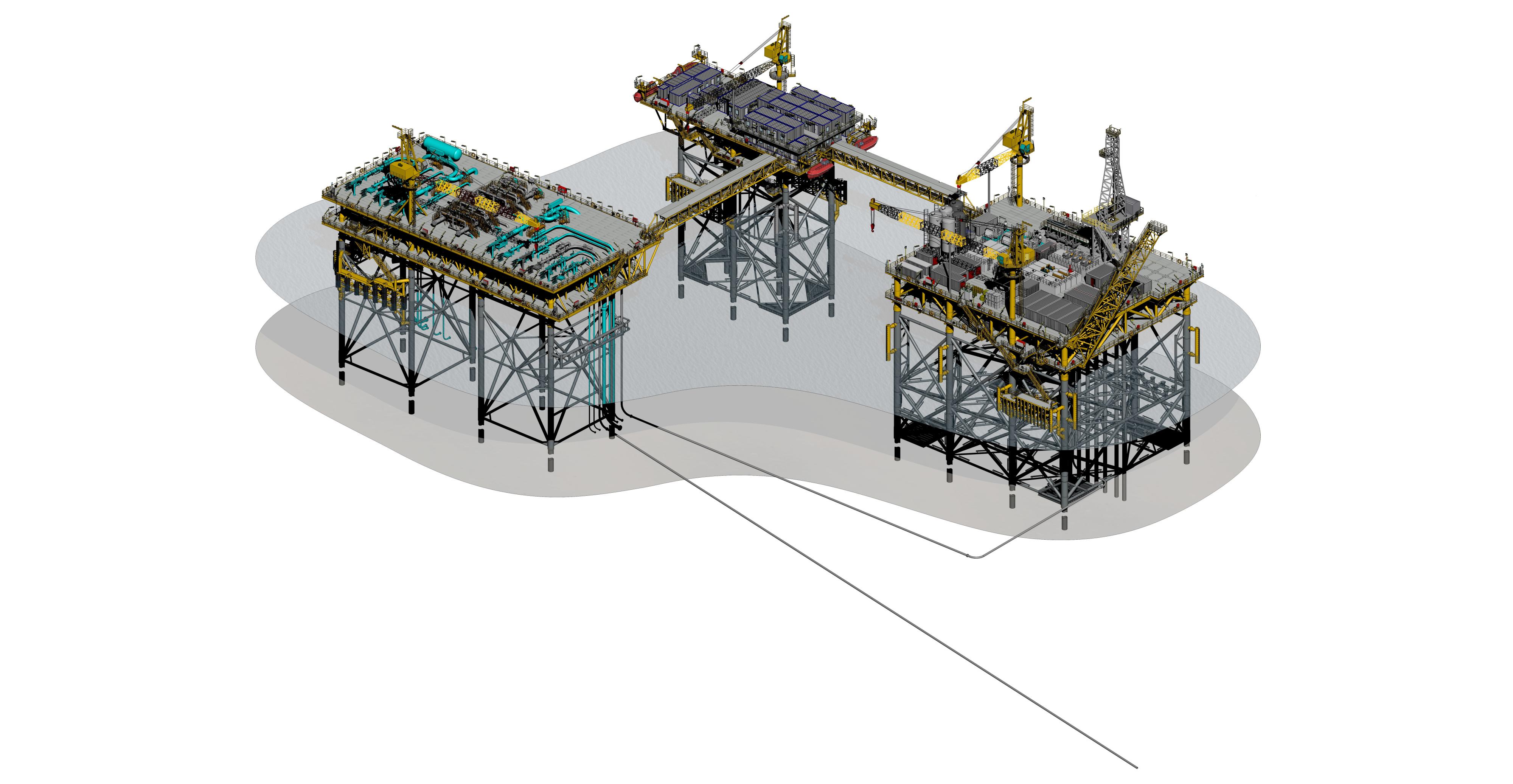

- Engineering of marine operations

- Development of method statements for preparation works (fabrication, preparation of vessels, barges, onshore handling of loads, weighing prior to load-out, upending of structures)

- Development of method statements for transportation, including sea-fastening

- Development of detailed method statement and their approval at MWS

- Development of method statements for offshore installation using crane vessels, as well as installation by means of launching and float-over, including design and development of procedures for jackets levelling following pile driving, and LMU structure design and development

- Technical assistance in marine operations

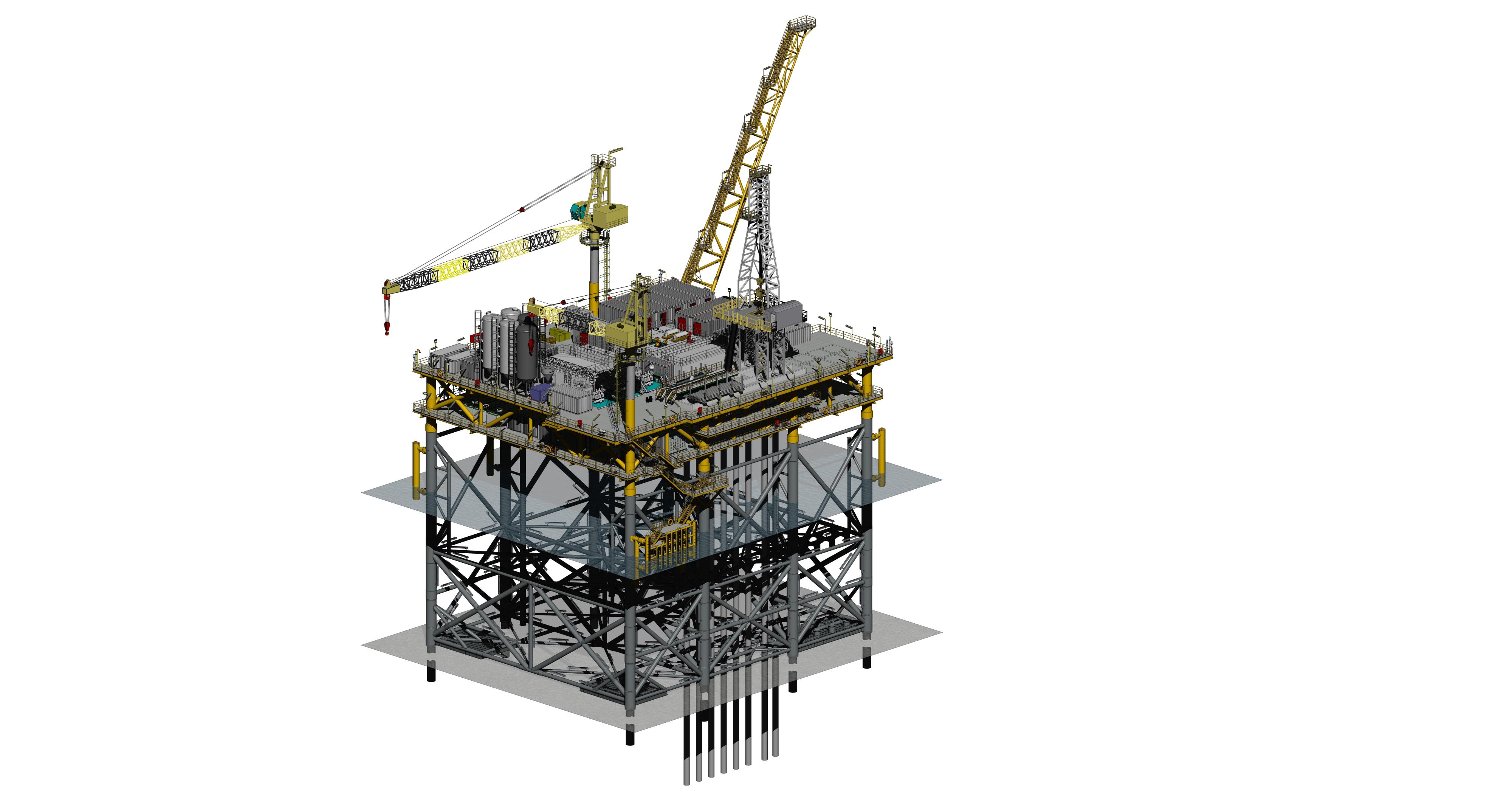

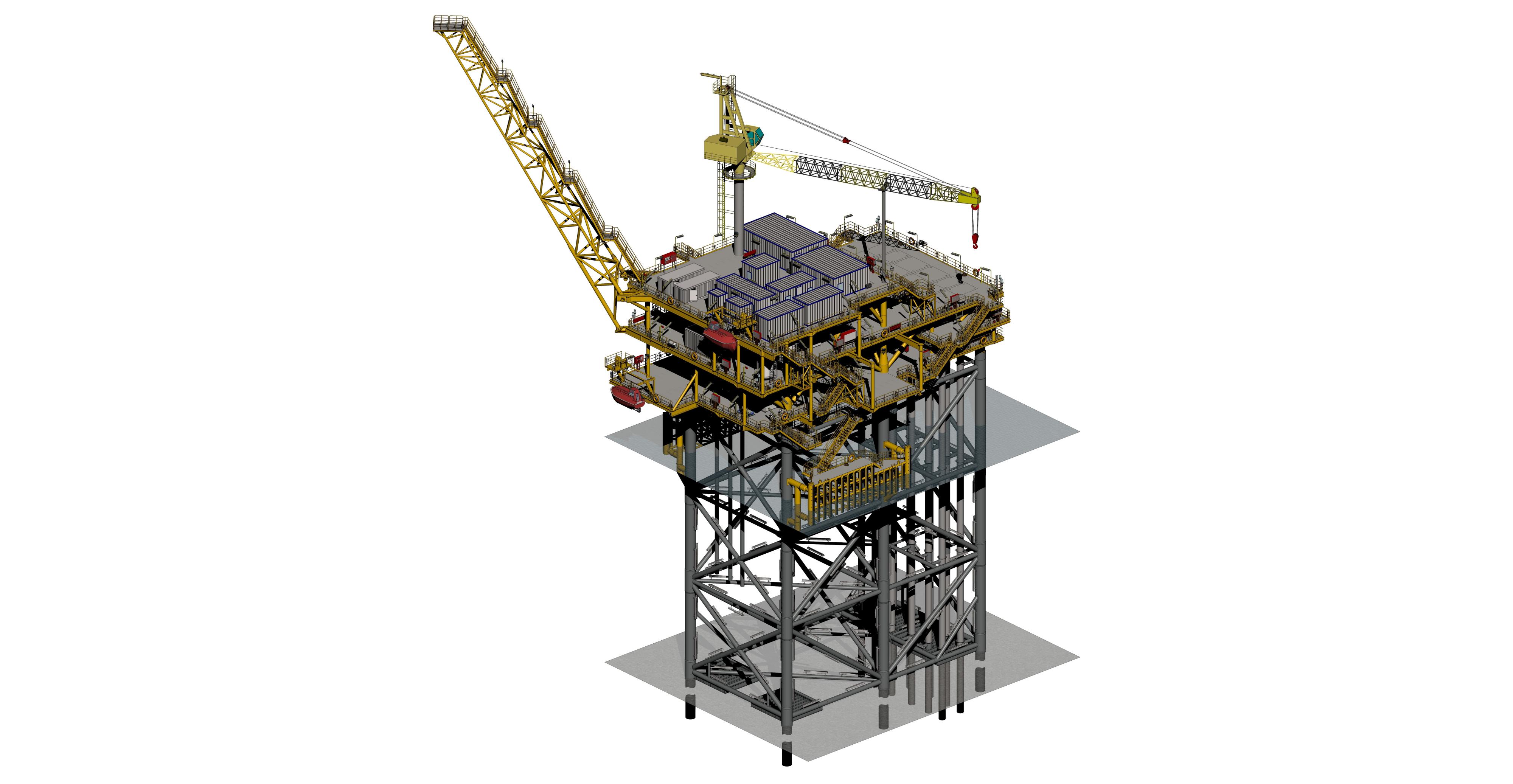

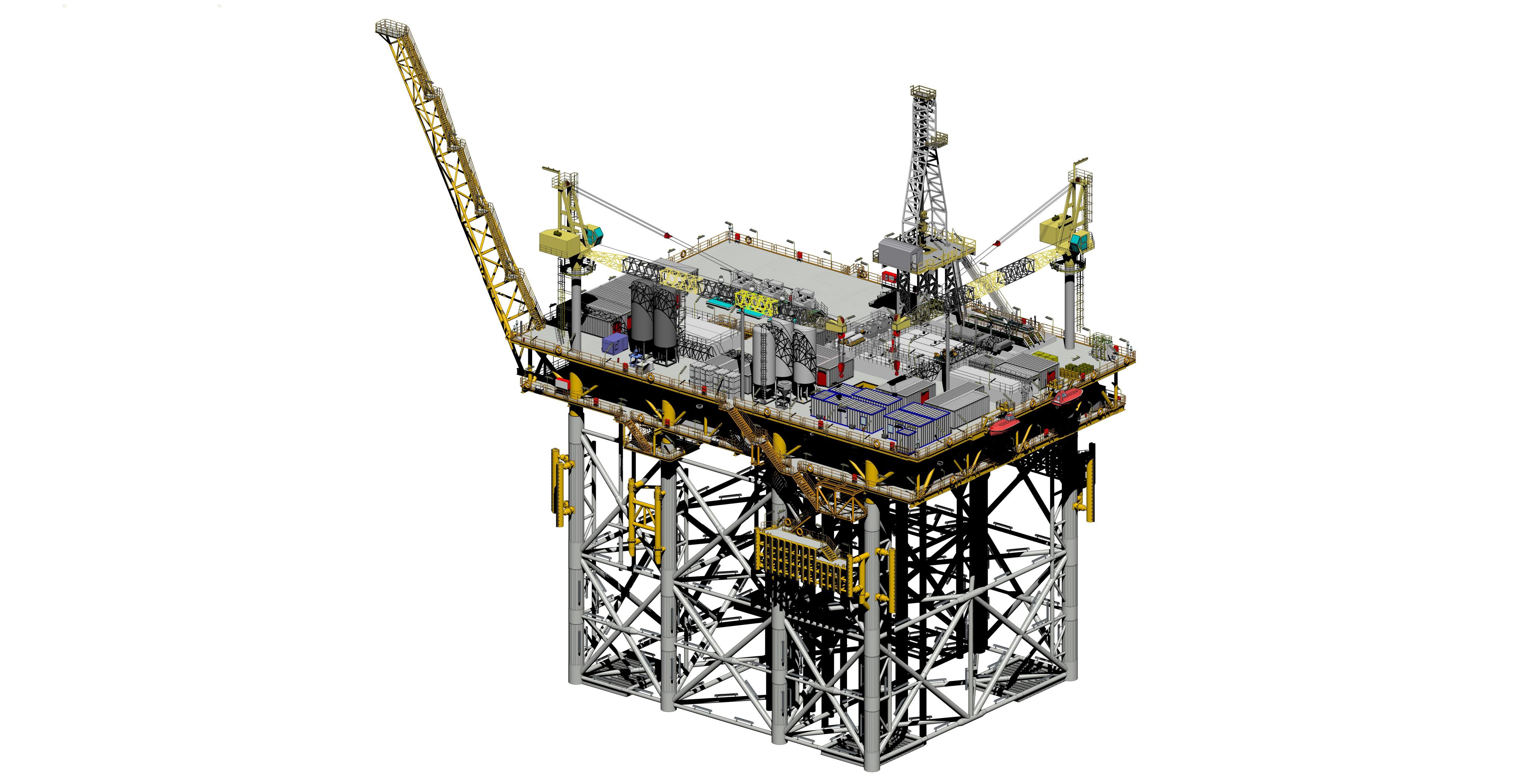

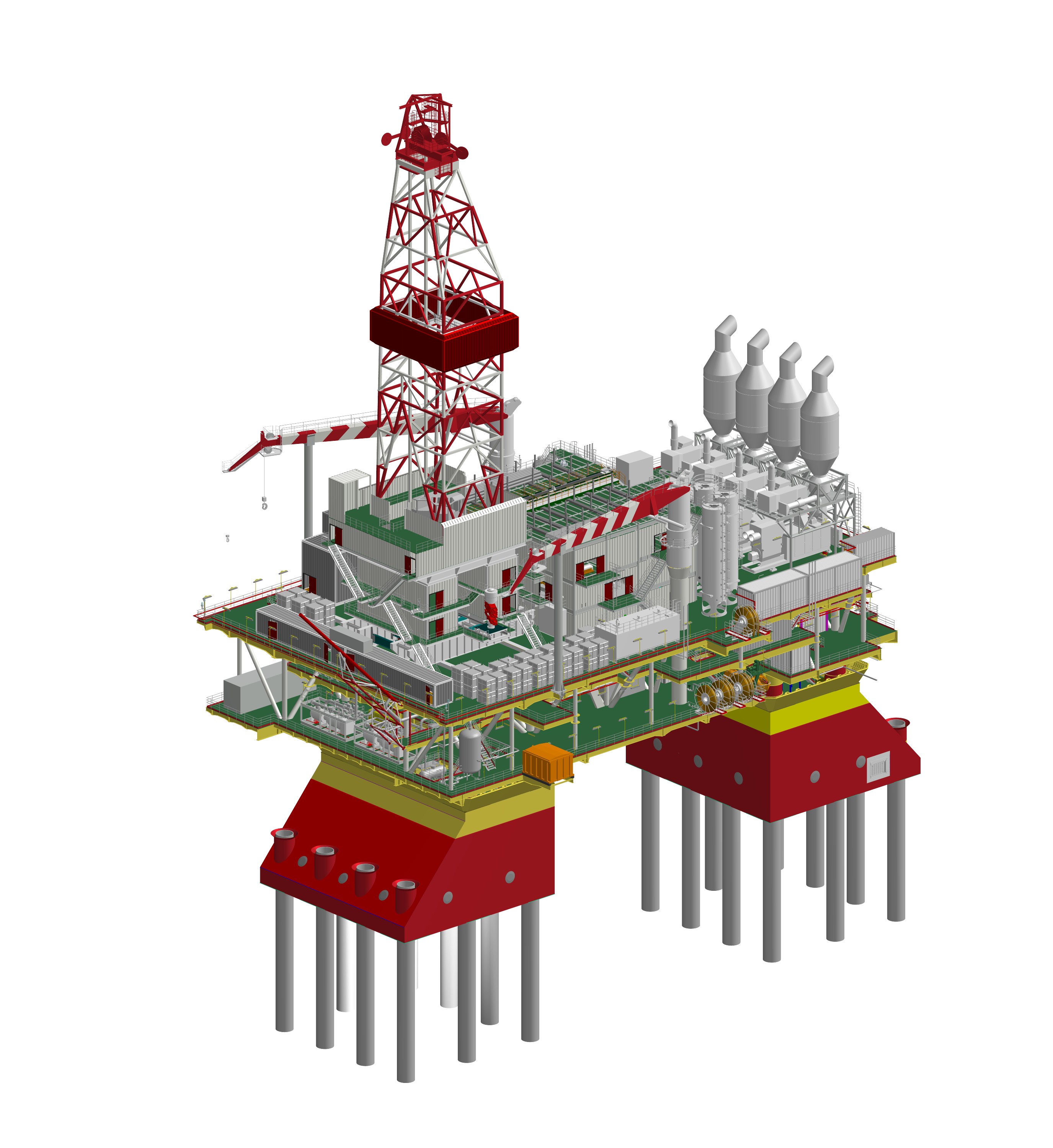

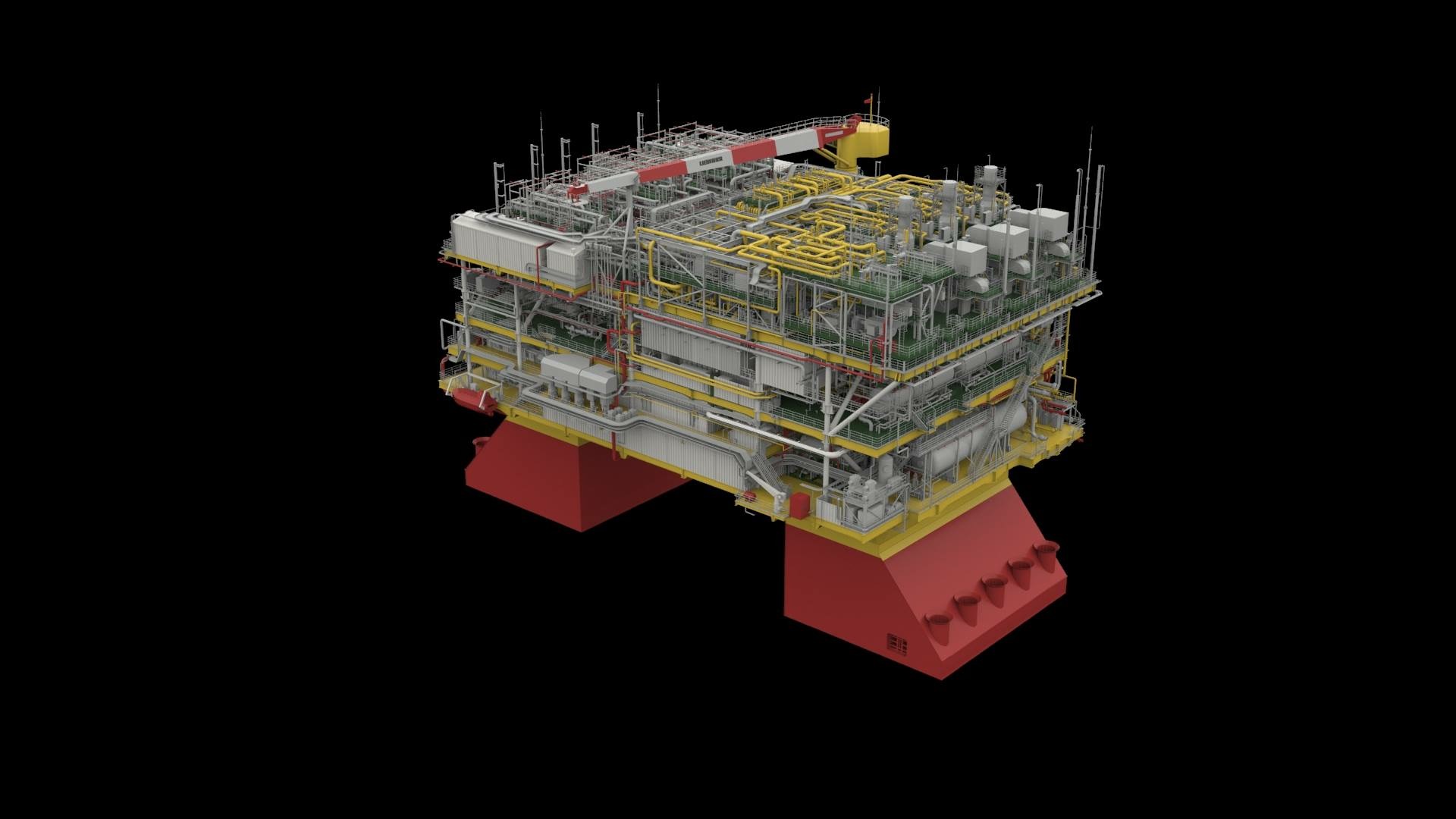

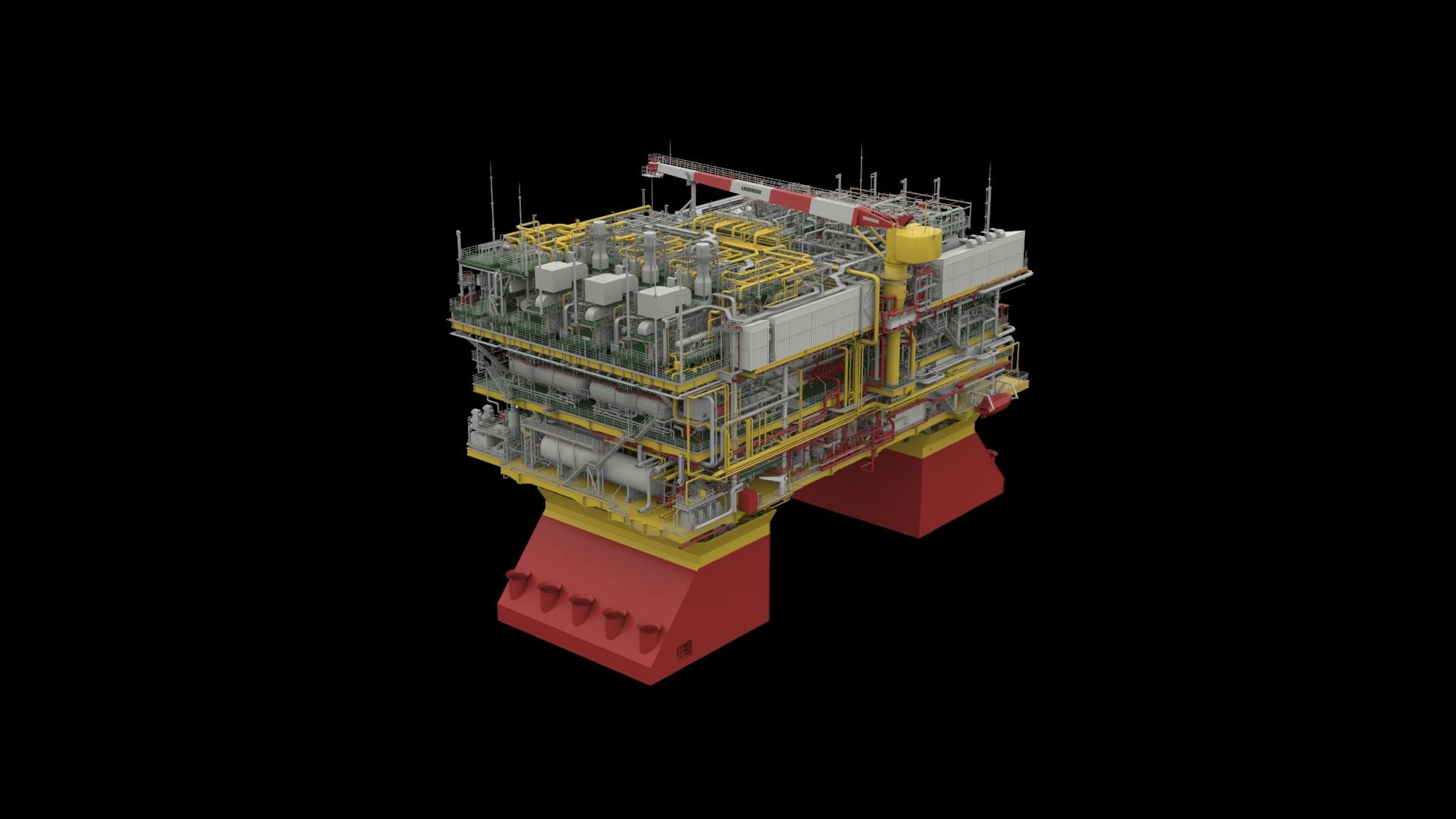

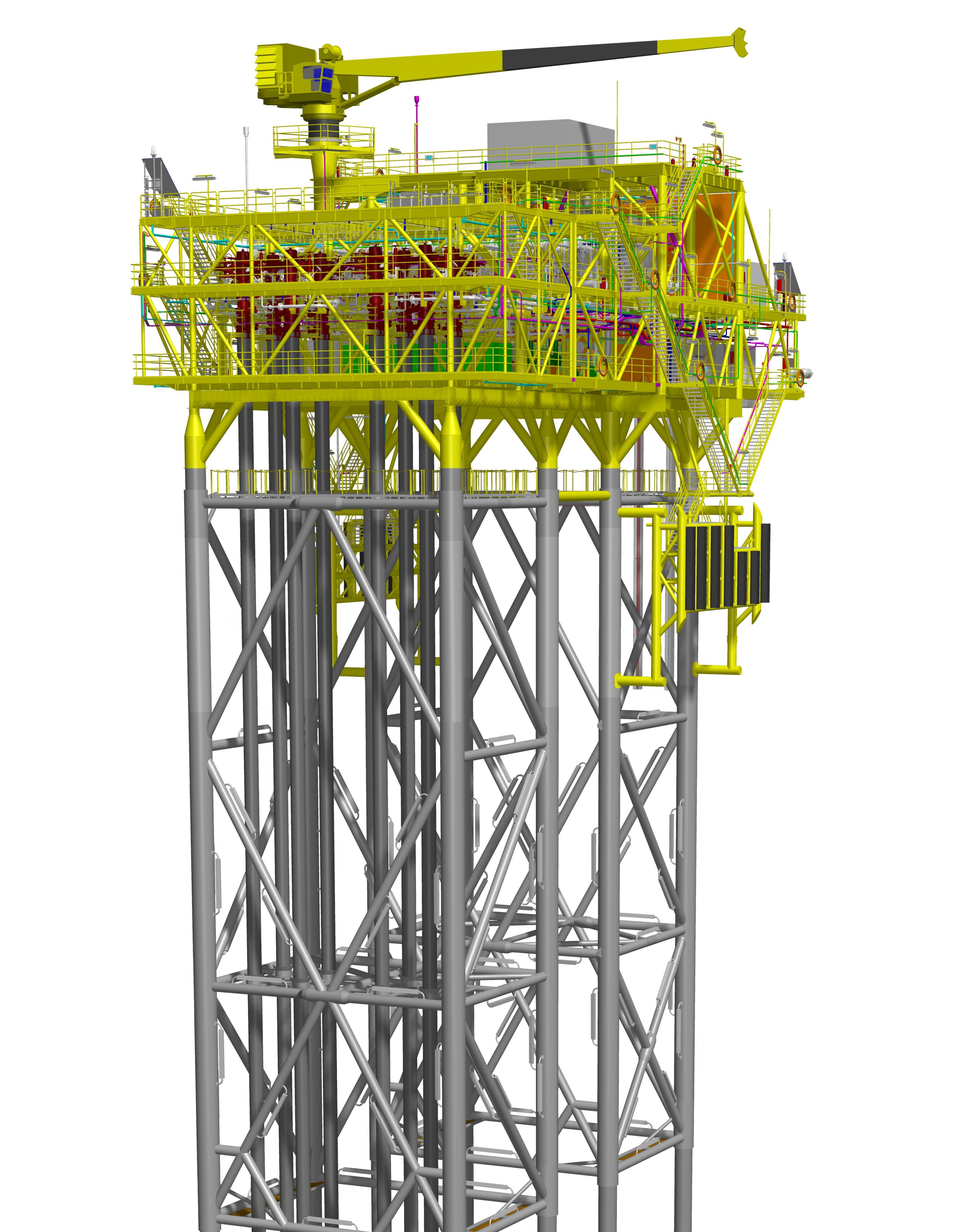

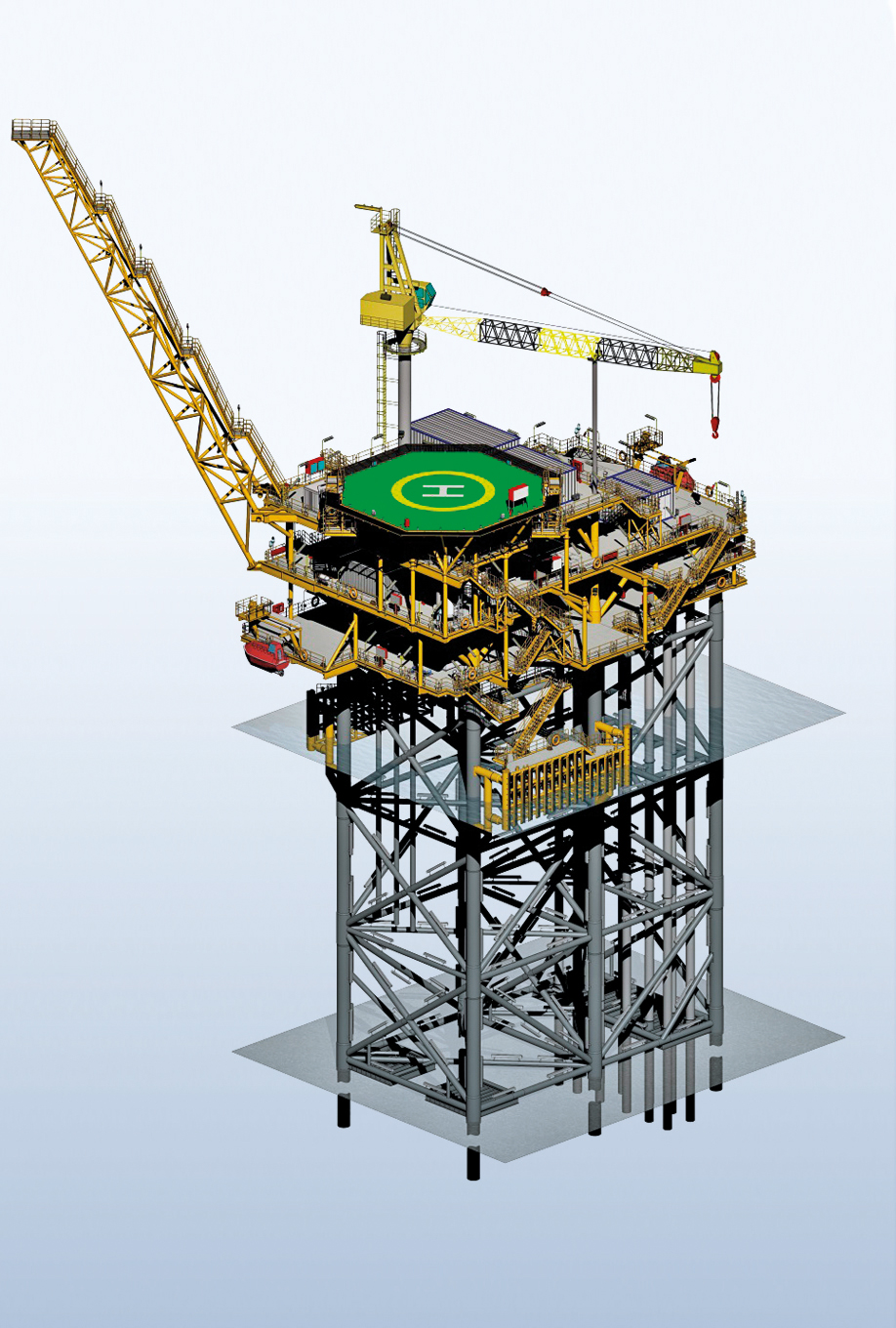

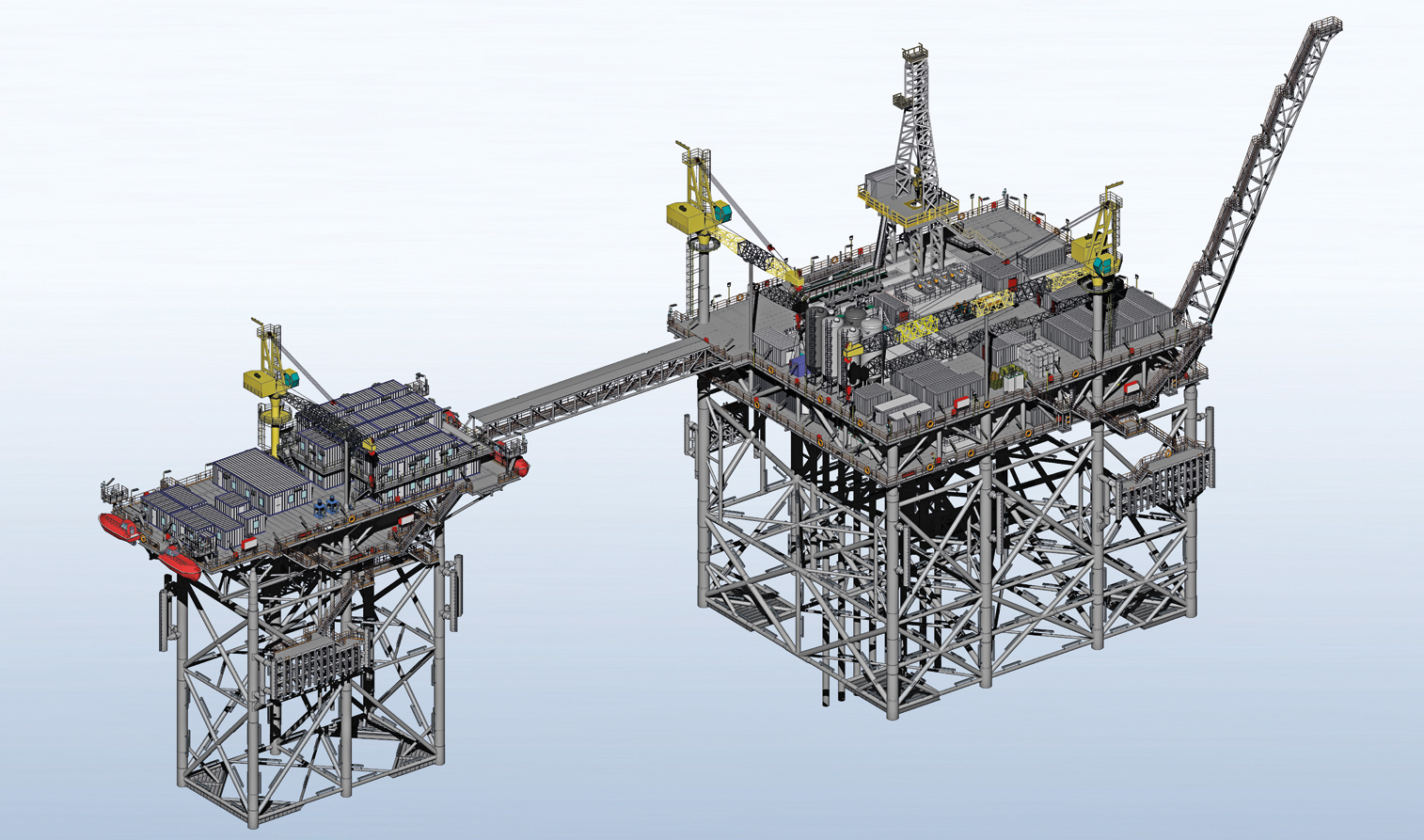

Photo gallery